How to choose a torque wrench for a car? Review of all points. Which torque wrench is best to buy for a car? Selecting a company and model

Snap type torque wrench

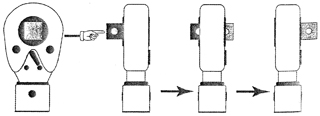

The most universal are click (limit) type torque wrenches. Designed to be tightened, usually clockwise, to a predetermined torque. There are varieties of wrenches that allow you to tighten fasteners counterclockwise. The design of such torque wrenches provides for switching the connecting square to the opposite side.

Outwardly it resembles a regular ratchet with a scale applied to the handle. These are the most convenient keys to use. Setup is very quick:

- Loosen the lock nut (1);

- Using the rotating handle (3) on the scale (2), set the required load (as on a micrometer);

- Secure the position with a lock nut.

The key is ready to use. During operation, when the set load is reached, a click is heard. It's very simple. This is a click type.

The error of such torque wrenches is about 4%, which allows you to carry out virtually all work related to car repairs. The only thing to consider when choosing torque wrench, this is the working range. It could be:

from 0.5 kg to 2.5 kg - 1/4" square

from 1.9 kg to 11 kg - 3/8" square

from 4.2 kg to 21 kg - 1/2" square

from 7 kg to 35 kg - 1/2" square

from 8 kg to 40 kg - 3/4" square

from 10 kg to 70 kg - 3/4" square

from 14 kg to 98 kg - square 1"

It is advisable to choose so that the required loads are within the operating range (not extreme values).

There are several types of click torque wrenches except what has already been described. They differ in the devices for setting the torque. For example, with setting the moment on the scale in the window. The value on the scale (2) is set by turning the ring regulator (1), having first pulled it out. It is believed that the accuracy of torque wrenches with a scale is slightly lower than that of analogues.

Accuracy of all readings torque wrenches should be checked regularly once a year or every 10,000 uses. So torque wrenches used by professionals at service stations and amateurs. The price of this torque wrench from 900 rub. up to 3000 rub.

Electronic torque wrenches

The most serious are considered electronic torque wrenches. Uncertainty of results tool no more than 1%, and the readings are displayed on digital liquid crystal displays in any measurement system (kg, pounds, N/meters). This one has a connector for connecting to a computer. And, accordingly, it is possible to print tightening data and other information (date, time, operation number, car make, purpose, etc.). But also price of electronic torque wrenches starts from 1000 euros.

Arrow torque wrenches

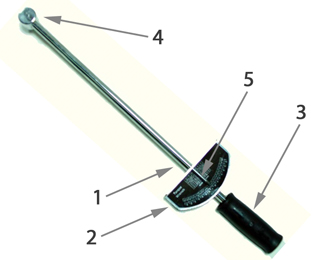

There is another variety torque wrench. These are the so-called arrow torque wrenches. A very cheap option (about 300 rubles). Attached to the body (1) is a scale (2), a handle (3), a square for socket heads (4) and an arrow (5). When tightened, the pointer remains in place, but the housing with the scale moves. The error of such torque wrenches is 6-8%. Such keys can break only when the load is exceeded.

Mechanical torque wrenches with a round scale and arrow are less convenient to use. The price and weight are higher than click ones, but there are buyers for them too. If performed well, the error is 2-3%.

We briefly told you about the main types torque wrenches. Which one to choose is up to you. Common sense will tell you that using torque wrench necessary not only when repairing the engine, but also when tightening any fasteners, including wheel nuts.

Before you buy, you need to know well how to choose a torque wrench for your car. This is a very necessary thing for a motorist; it will be useful even for those who do not like to tinker with wheels and other parts of their car.

In the end, if you splurged on good shoes for your car and changed them, it will be very disappointing to lose them when you tighten the wheel nuts too vigorously (for example, when setting the wheels using a non-adjustable gun in some tire shop). And if you don’t apply enough effort, this is exactly what will happen: the casting will burst from overly zealous tightening. And if there is insufficient tightening, on the contrary, there is also the possibility of losing a bolt or the wheel itself while driving.

Don’t forget about the ease of use of such a tool (this is the only reason why it can be purchased as a kit that can be transported in the trunk). And since it is bought for quite necessary work, the accuracy of the measurements it provides becomes very important.

How to choose a torque wrench for a car a person who has never used it before and doesn’t know what to focus on? Carefully delve into the description of the varieties of such keys and decide what he is willing to sacrifice: a larger amount from the stash or the accuracy of the data on which the longevity of his car depends.

Types of Torque Wrenches

Depending on what goals you pursue by purchasing such a key and how often you plan to use it, choose from three varieties.

- Switch. The simplest, the cheapest - and the most unreliable. The data shown to them may differ from real ones by as much as 10%. The maximum that such a key can squeeze out is 280 Nm. The result is determined by the eye, which, as we know, can always fail. For simple work that does not require high precision, it is quite suitable, although experts do not consider it a tool - so, something like a sledgehammer, which in theory is also a tool;

- Snap, called by motorists a ratchet. It is most popular among car owners and is fully recognized by auto mechanics. The error can reach 5%, which is absolutely nothing for home and garage use. The range of recorded forces is from 40 to 360 Nm. There are ratchets for car mechanic and professional use; their error is a maximum of 3%, but the cost will be much higher than amateur options, which will be simpler;

- Electronic. Equipped with a digital scale, light and sound indication of effort. Measurement range 20-350 Nm with an error of less than 1%. Such keys are purchased mainly by service stations, services and factories. It costs an order of magnitude more than a ratchet, even one suitable for professionals.

What do we pay attention to?

The cheapest torque wrenches are those with a non-removable ratchet. Considering that the bolts and nuts in cars come in different sizes, a non-separable wrench is not always an assistant. These keys will have to be taken in three sizes. So a better purchase would be a torque wrench with removable ends. For the most part, they are sold as a kit that covers all needs; but some manufacturers offer the possibility of custom configuration, so you can slightly reduce costs by adding attachments that you consider unnecessary.

Most torque wrenches are intended to be used for tightening only. However, in the case of some nut procedures, this is not always what you want. If fiddling with reverse-threaded nuts is likely, you will have to fork out for a wrench that works in different positions. Its use involves 3 modes: fixed, tightening and unscrewing. Of course, this will no longer be budget option. Finding something like this for less than 3-3.5 thousand rubles is problematic.

Let's learn to work with it correctly

Before starting the planned work, the force with which you need to act on the nut or bolt is set on the ratchet (as well as on any other torque wrench, if you have chosen an alternative option). To do this, the knob is unscrewed to the desired value. When it is reached, a characteristic click will be heard, for which this type of key received its name, both official and popular. Curious people sometimes wonder: what will happen if, after achieving the ordered effort, you continue to press?

The torque wrench will work like a primitive wrench, making warning clicks, and you will break the nut or damage the part. In this case, the key itself will lose its functionality much earlier than planned by the manufacturer.

What else should not be forgotten, so this is about returning the key to its original state after completion of work. There is a spring inside it, which measures the amount of force. If it is constantly in a compressed state, metal fatigue will overtake it quite quickly. As a result, the error will begin to grow rapidly.

You probably already understood the basic principles of how to choose a torque wrench for a car. All that remains is to choose a manufacturer and go to the store.

What happens if you don’t tighten enough, for example, the fastening nuts on the wheels of a car or, conversely, overtighten them? In the first case, they will quickly become loose, in the second, the thread will simply break off. The result is the same - the wheel will fly off the axle.

How to achieve high accuracy of fastening of each bolt, screw and nut? It is difficult to focus on the force with which the worker fixes the nuts. Firstly, this will be an approximate force, and secondly, what if you need to tighten several dozen of them per shift? There is a way out - use a durable and accurate torque wrench that clearly controls the force with which any threaded connection is tightened.

Read on to learn about the operating principles and types of these keys, as well as the most popular models.

Classification of torque wrenches and operating principle

Before you start choosing a torque wrench, you need to know what they are. This is very important: each type has its own design and operation features, therefore, its own scope of application in which its use will give maximum results.

Limit (spring) type keys. The body of the key and the rotating part are marked with a scale. First you need to loosen the lock nut, then, by rotating the handle, make sure that the zero mark on it coincides with the required mark on the key scale. This way, the required tightening torque will be set. Next, to add the value on the handle scale to the first set value, rotate the handle clockwise until it coincides with the next zero value. After this, you can fix the lock nut and tighten the fasteners. There is no need to monitor the set force value: when it is reached, you will hear a click, which will indicate that the fastener is tightened to the specified value.

Who will need these? For example, mechanics at service stations, when they need to tighten a large number of nuts per shift, and high accuracy does not matter big role. The error is ± 4%.

Arrow keys. The easiest to set up and use. They consist of a body to which a scale is attached, a handle, a square for socket heads and a pointer. It is not difficult to work with such a wrench: during tightening, the body along with the scale is deflected, and the arrow remains in place, showing the torque value. The error of the devices is quite large and amounts to 6 - 8%, and the not very convenient case does not allow the tool to work in hard-to-reach places. However, despite the shortcomings, such wrenches are very convenient when the process of tightening critical components needs to be controlled - you can see with what force the nut is tightened.

Arrow keys. The easiest to set up and use. They consist of a body to which a scale is attached, a handle, a square for socket heads and a pointer. It is not difficult to work with such a wrench: during tightening, the body along with the scale is deflected, and the arrow remains in place, showing the torque value. The error of the devices is quite large and amounts to 6 - 8%, and the not very convenient case does not allow the tool to work in hard-to-reach places. However, despite the shortcomings, such wrenches are very convenient when the process of tightening critical components needs to be controlled - you can see with what force the nut is tightened.

Digital keys. The most accurate type of instrument - the error is about 1%. This type of key works as follows. There are several buttons on the case: to turn on the device, select the torque unit, set the desired torque value and adjust it, and a buzzer to sound a signal. After setting all the parameters, you can start working - while tightening, the display shows the current force value. When the required value is reached, the key emits a sound signal.

Where to use such keys? At the stations maintenance for tightening particularly critical connections, for example, for securing a cast alloy wheel, which can crack even if the force is slightly exceeded. The digital key is also convenient to use at industrial enterprises for the repair and maintenance of machine tools, railway transport etc.

Features of using torque wrenches

When purchasing a tool, you want it to work not only accurately, but also for a long time. To do this, it is important to follow these steps:

- after completing the work, always set the force value to 0, otherwise the spring will stretch and the key will deteriorate;

- do not use the wrench as a regular tightening tool, otherwise it will risk very rapid wear - use it only at the final stages of tightening the fasteners;

- you cannot use a wrench if the tightening force you need exceeds the maximum for this tool;

- It is forbidden to subject the key to strong impacts - this threatens rapid failure.

After use, be sure to clean the tool with a clean rag and periodically lubricate it. To ensure that the key does not lose its accuracy, it needs to be checked approximately once every 1000 uses.

How to choose a torque wrench?

From tool selection to technical specifications The quality of the work performed and its durability directly depend. What are the main parameters of torque wrenches? Let's take a closer look.

- Maximum force (torque)- measured in newton meters (Nm) and directly affects the work that can be controlled with its help. It is better for a car service or workshop to purchase several keys with different force ranges to perform any operation, for example, with a force range from 28 to 200 Nm and with a force range from 100 to 700 Nm.

- Square- indicated in inches. Before buying a torque wrench, decide what size nuts you will most often tighten, and purchase a tool with the appropriate square size. To help you get your bearings, we present a table of the correspondence between force and square size, where 10 Nm is approximately 1 kg/m.

| Force, Nm | Square, inches (") |

| From 5 to 25 | 1/4 |

| From 19 to 110 | 3/8 |

| From 42 to 210 | 1/2 |

| From 70 to 350 | 1/2 |

| From 80 to 400 | 3/4 |

| From 100 to 700 | 3/3 |

| From 140 to 2000 | 1 |

Advice. When choosing the force with which you will tighten the wrench, be guided in this way: the value you need should be approximately in the middle of the range of force values of the wrench itself.

- Weight and length- affect the degree of convenience of working with the key.

So, it will be useful not only for professional workers in auto repair shops and service stations to check the tightening force, but also for amateur motorists. By purchasing the tool, you receive:

- the ability to tighten nuts with a force from 15 to 980 Nm;

- the ability to work with different landing squares for the head - from 1/2 to 3/8 inches;

- confidence in the strength of the resulting structure.

About six months ago, I got hold of a wonderful and inexpensive Force 5-25 Nm torque wrench. Immediately after the purchase, I tried to tighten a few bolts with it, as a test, and put it on the shelf, because maintenance of the motorcycle was not planned for any time soon. Half a year later, when I needed the key, I was horrified to discover that after the last use, I forgot to unscrew the knob to the zero position... it turns out that all this time the tool was lying in a “tense” state...

“This is unlikely to affect the accuracy of measurements better side“, I thought, and decided to subject the key to a simple test. In order to understand whether it is possible to continue to use this tool, or whether my carelessness led to its damage... To check, we need an ordinary household steelyard and 10 minutes of free time. Anyone interested, welcome to the cut!)))

1) First of all, let's check the accuracy of the scales. The “passport” for the scales indicates the measurement accuracy of +-10 grams. However, let’s not take the manufacturers’ word for it and weigh two liters on them cold water... The scales turned out to be quite accurate, let's proceed to step two...

2) Take a 8-mm bolt, screw two nuts onto it (one all the way to the bolt head, and just tighten the second a little), clamp it in a vice, tighten the bolt to the limit with an ordinary long wrench (the tightening torque is clearly more than 25 Nm).

3) Place the key on the prepared bolt so that the knob looks either up or down (yes, it is more convenient to take measurements when the key knob is positioned horizontally, but in this case the calculations become much more complicated).

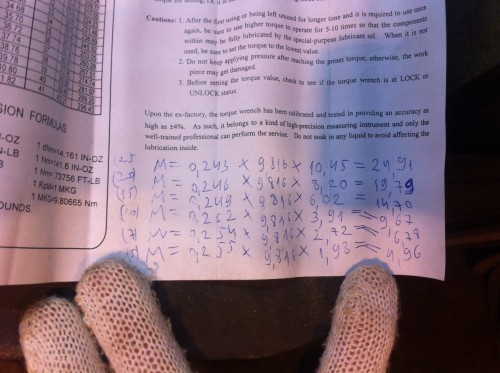

4) We set any tightening torque on the key, and smoothly, gradually pull the steelyard hook at a pre-selected, conspicuous place on the collar until the key works. We remember the readings of the scales at the moment the key is activated. The direction of the force with which we pull our steelyard must be strictly perpendicular to the key collar. After this, we measure the distance from the center of the head of our key to the place on the collar to which we applied force. The experiment must be repeated several times to different meanings tightening torque. For my key model, the length of the wrench changes depending on the set torque, so I measured the arm (the distance from the center of the wrench head to the point of application of force) after each change in the tightening torque. We record the results in a table for convenience and clarity.

5) We calculate the experimental values of the tightening torque using the formula: M = m*g*l

where M is the desired theoretical tightening torque (Nm), m is the readings of our steelyard (Kg), l is the shoulder (m), g is the acceleration of gravity.

6) We compare the obtained theoretical results with the moments set on the key. I took measurements for 5, 7, 10, 15, 20 and 25 Nm.

For my key model, the manufacturer stated a permissible error of 4%. We see that the obtained values fall within this error.

Conclusion: the key is working and suitable for use.

There are long and heated debates about whether ordinary car enthusiasts need a torque wrench. Meanwhile, everything in this situation is, in general, quite simple. Let's figure out what a torque wrench is, how to use it and how to store it.

What is a torque wrench

In essence, this is an ordinary wrench, which is equipped with a dynamometer, and allows you to tighten threaded connections with a precisely specified force. In other words, if the documentation for your car says that the wheel nuts should be tightened with a force of 110 Newton meters, then you can only achieve this condition using a torque wrench. It is the accuracy of the tightening torque of a particular unit or connection that is the advantage that torque wrenches provide. Let us now consider the main types of this instrument.

Types of torque wrenches

From top to bottom: dial, dial, electronic and limit torque wrenches

Torque wrenches can be divided into two main types:

- Indicative;

- Limit;

Indicator torque wrenches, in turn, are:

- Scale;

- Switches;

- Electronic;

Electronic keys, of course, have the highest accuracy, while the other two types cannot boast of high accuracy of readings.

As for the limit keys, the required force value is set here before starting work. And when you reach this value, the key makes a clicking sound or another alarm mechanism is triggered.

Basically, those who use such tools choose limit keys. Electronic keys are too expensive, and besides, in everyday life, perfect accuracy is not required for a simple car enthusiast. In addition, it is not always convenient to control the dynamometer readings. And with the limit key, everything is quite simple. Set the desired value and you work without being distracted by any scales, arrows, or dials. Therefore, even experienced service station technicians prefer keys of the extreme type. In addition, side-mounted torque wrenches maintain high operating accuracy longer, compared to indicator non-electronic analogues.

There are also one-way and reversible keys. The former are only suitable for tightening right-hand threads, while the latter can also work with left-hand threads. Consequently, reverse models will be much more versatile.

Torque wrenches also differ in the range of measured forces. The smallest ones operate in the range of one to six Newton meters, and the most common automotive torque wrenches can operate in the range of forty to two hundred Newton meters.

So does a car owner need a torque wrench?

Some car owners and even some auto mechanics argue that a torque wrench, in general, for the average car enthusiast, is a useless and unnecessary thing. The wheels, they say, can be tightened without much precision, but the rest is the job of a specialist.

Meanwhile, these craftsmen themselves do not deny that they carry out repairs and replacements of many components on their cars themselves. Another thing is that over time, experience appears and a fairly accurate feeling of the sufficiency of the effort being applied, especially when it is a familiar and thoroughly familiar car. What should those who do not have such experience do? Broken bolts, broken studs, broken nuts or heads can all be the result of not having a torque wrench. Especially today, when foreign-made cars actively use various alloys and non-ferrous metals.

In addition, a torque wrench allows you to achieve such an important thing as uniform tightening of all bolts or nuts, which even on a wheel will not be at all superfluous, but there are situations when this is a prerequisite.

By the way, a torque wrench will also be useful for modern cyclists. After all, new, lightweight models of two-wheeled vehicles include aluminum, carbon fiber and other materials that, when overtightening connections, can crack, collapse and become unusable.

How to use a torque wrench

Actually, there are no special differences between working with a regular wrench and a torque wrench. You set the required force if it is a limit key, or you control it visually if it is an indicator key. And then, you tighten the nut or bolt until you reach the required torque, that's all.

The only thing is that no lever arm extensions are allowed when working with torque wrenches. In other words, if you can put a piece of pipe on a regular wrench to increase the applied force, you can’t do that here. The key, of course, will not deteriorate, but there will be no talk about its accuracy. Therefore, you will have to work exclusively with your hands. The required values for the force in a given situation should be looked for in the documentation for the car or other technical equipment with which you plan to work with such a key.