How does power steering work. How does power steering work? Its principle and full description

Today I will talk about power steering(GUR). From this article you will learn what power steering is, what you need to watch out for when operating a car with power steering? And what should you pay attention to when buying a car if it has a power steering?

Hello dear blog readers.

Hydraulic power steering (HPS) is the hydraulic part of the steering mechanism, which serves to facilitate driving. As you understand, the name is directly related to the principle of operation. The use of power steering on cars began with trucks. And this is understandable. Imagine how much effort it takes on the steering wheel to turn such huge wheels on a heavy car. And the power steering allows you to turn the steering wheel with one finger.

The power steering is a system consisting of

1) a pump that creates pressure and circulation of oil in the system;

2) a distributor that distributes the oil;

3) a hydraulic cylinder that converts oil pressure into the movement of a piston and rod, which in turn turns the wheels through a system of levers;

4) special oil, which transmits force from the pump to the hydraulic cylinder and lubricates all friction pairs.

The tank serves as a reservoir for oil. There is a filter in the tank, and a dipstick in the plug for determining the oil level (not for all machines). When you start the car engine, the belt starts to rotate the power steering pump, and the steering wheel becomes easy to turn.

You can check how hard it is to turn the steering wheel without power steering

To do this, do not start the engine and try turning the steering wheel. The hydraulic power steering not only provides comfortable and easy steering, but also increases driving safety. During the operation of the power steering, the shocks transmitted to the steering wheel from road irregularities are softened. It helps to hold the steering wheel if front wheel pierced at speed.

If you have a power steering on your car, then you can always keep the car on the trajectory you need (the steering wheel will not break out of your hands). An important indicator of a good power steering is the presence of feedback, the so-called feeling of the road. In practice, the more expensive the car, the better the feedback due to the power steering design, and vice versa.

When you turn the steering wheel, there is feedback from the steered wheels through the hydraulic booster to the steering wheel. You feel that, for example, on a slippery road, the steering wheel turns easier than on a dry one. And this feeling allows the driver, through the feeling of the road surface, to correctly rotate the steering wheel in any conditions. Without this feedback (if the steering wheel always rotated with the same effort), it would be difficult for the driver to determine the direction of the steered wheels.

Cons of power steering

But despite the large number of advantages and low cost in production, the power steering has many disadvantages. The power steering works directly from the engine. Thus, it takes some of the power from the engine, even when the car is driving straight or standing still, and the driver is not turning the steering wheel. If your car is equipped with power steering, then you should know that you cannot hold the steering wheel in extreme positions for more than 5 seconds. Because in extreme positions, the oil overheats, and the power steering may fail.

It is also undesirable to gas with the wheels turned out. It is necessary to monitor the oil level in the tank, change the oil in time, check the condition of the belt that drives the power steering pump, monitor oil leaks. And a car with power steering has poor feedback from the road at high speeds (the steering wheel is light).

All these shortcomings are devoid of electric power steering (EUR). But in any case, driving a car with power steering is much more comfortable than without it. If the power steering belt breaks, you will still be able to control the car, only the steering effort will be heavier, but you will be able to continue driving and get where you need to go, but without comfort. After this, do not over tighten with the replacement of the belt, because the power steering gear is designed to operate under oil pressure. And if the pressure drops (belt break), then an increased load will act on the parts of the steering mechanism, and the steering will quickly fail.

What should be monitored in the daily operation of the car?

Periodically (you can combine checking the power steering system with checking the engine oil), you need to check:

1) oil level in the hydraulic booster reservoir (by marks between min-max or by dipstick level).

To do this, you unscrew the reservoir cap (the engine is off) and look at the oil level on the dipstick built into the reservoir cap;

2) inspect the belt that sets the power steering in motion for cracks, delaminations, slips;

3) monitor the tightness of the system. Inspect the entire system for leaks, if there are oil leaks, then they must be eliminated, since without oil the steering mechanism quickly fails and its repair will be expensive. Easier to monitor and fix in time;

4) Replace the filter element and fluid once every 2-3 years. Change the oil if its color has changed or it has become cloudy;

5) special attention should be paid to the power steering if vibration is felt on the steering wheel, the car does not obey the steering wheel when cornering, or the steering wheel does not work correctly when the air conditioner (climate control) is turned on, or the steering wheel is hard to turn;

6) in winter very coldy when the oil is thick, do not hold the steering wheel in extreme positions and avoid hard taxiing when the car is not warmed up.

Please watch the power steering!

It's easy - open the hood and look at the power steering system and it will take no more than 3 minutes.

It does not require special knowledge to see leaks or look at the dipstick. The power steering is a fairly reliable mechanism and, most often, the reasons for its failure are improper operation (the steering wheel is held for more than 10 seconds in extreme positions) and insufficient control (the driver rarely opens the hood and does not monitor the oil level in the power steering reservoir and does not change it on time oil, filter and belt).

What to look for when buying a car equipped with power steering?

The main malfunctions of the power steering can be determined on the spot, without leaving the inspected car on the road. When buying, open the hood of the car and carefully look into the engine compartment. Watch out for oil leaks around the steering gear. Unscrew the power steering reservoir cap and look at the dipstick (if any).

There are marks on the dipstick or on the tank itself and the oil level must not be lower than these marks. Drop a drop of oil from the dipstick onto some surface (you can use your finger) and look at this drop. The oil must be clear (no cloudiness) and free from impurities, the color must be determined. Screw back the power steering reservoir cap. Inspect the belt that drives the power steering. There should be no cracks, delaminations on the belt, protruding threads of the belt cord are not allowed.

A car without steering is quite difficult to imagine. But at the dawn of the automotive industry, there was such a thing. When heavy vehicles began to appear, one problem arose: in order to unscrew at low speeds, one had to make simply titanic efforts. Therefore, design engineers were puzzled by the issue of facilitating this process.

The brainchild of their brilliant thought was the power steering. At first it was vacuum and did its job rather poorly, then it appeared, and the electronic amplifier was the pinnacle of technological progress. If in the second one oil is used as a working fluid, then in the third one the microcomputer analyzes the steering angle, after which it rotates the wheels with the help of an electric motor. Today we will talk about power steering, its features, principle of operation and some points that will significantly increase its service life.

General position

The device and principle of operation of the power steering consists of the following elements:

- pump;

- distributor;

- , which transmits force to the wheels;

- filling tank.

And now let's look at the points, how the power steering works:

- When turning, the valve installed in the distributor opens or closes. Allowing the oil to flow one way or the other.

- The power steering pump is driven by the car's engine through a belt.

- Depending on which way the steering wheel is turned, the oil supply valve opens or closes, freeing or filling a special reservoir.

- Depending on the degree of filling of the tank, the wheels turn in one direction or the other.

As you can see, everything is very simple.

But, in fact, the hydraulic booster is a rather complicated device. Therefore, it requires regular maintenance.

If you do everything right and constantly change the oil in the system, then the power steering will last long years. But, if done incorrectly, this device can be ruined in 5 seconds!

pump belt

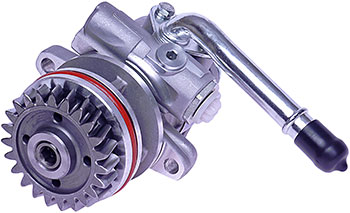

The most complex device in the entire power steering system is the power steering pump and its belt. It consists of many small parts, which in theory should serve happily ever after, but some owners can break down very quickly.

The impeller, which contains the power steering pump, rotates constantly, which creates a continuous flow of oil. It is driven by a belt thrown over the shafts of the engine and the power steering itself. They spin at the same speed no matter how fast the car is going.

And here lies another interesting point: during idle time, that is, when the engine is turned off, the hydraulic booster will not work!

It often happens that the belt wears out over time. And then the worst thing happens - the control suddenly becomes very tight, because the driver has to turn the wheels on his own. It is possible to cope with this situation, but at first it seems as if the steering wheel is jammed. Often, this second is decisive! And some drivers start to panic and even after some time they do not understand that it is still possible to turn the wheels. As a rule, this leads to an accident.

Turning wheels and deadly 5 seconds

As a general rule, modern power steering can fail if you keep the steering wheel turned for 5 seconds. During this time, such pressure is created in the tank that they break. So watch this moment.

Characteristics of hydraulic boosters

The most main characteristic- this is the speed of the response of the hydraulic booster to the steering wheel. AT good systems it is 0.1 - 0.2 seconds, that is, it reacts almost instantly. If you ordered a Chinese system, then save yourself from possible accidents - do not install it! There were cases when the response time of the device reached 1-2 seconds! As you can see, this is a lot.

The next is smoothness. This is also a very important characteristic of the hydraulic booster, because when the car turns jerky, the consequences will not only be unpleasant sensations for passengers. Other precise mechanisms installed in the vehicle may be affected.

Working move. If it is insufficient, then the car simply will not be able to turn around as sharply as it was intended by the designers.

How to change the oil in the power steering

There is nothing complicated in this:

- Through the filler neck of the barrel, select the used oil with a syringe (change it every year or two).

- Now remove the return tube from the barrel and place a container under it.

- Turn the steering wheel to different sides. The power steering pump must not be driven by the motor. It is better to turn off the car completely or remove the belt from the power steering shaft.

- After the return hose stops spraying oil when turning the steering wheel, put it back on. Also wear a belt.

- Now fill the system with oil. Pour until it stops leaving the keg.

- Turn the steering wheel and check the keg. If oil is still leaking, add it.

- Start the engine and turn the steering wheel again. It should spin easily.

- Shut off the engine and look into the barrel again. Top up if required.

Do-it-yourself power steering repair

Remember, the hydraulic booster is a very precise mechanism, most of the breakdowns of which can only be done in specialized auto repair shops. But, some breakdowns can be “cured” on their own:

- Overheat. Most likely there is not enough oil in the system.

- The appearance of dust and dirt. Remove the tubes and flush them.

- Liquid leakage. The pressure is too strong and the clamps that secure the pipes cannot provide a reliable connection.

- The wheel began to spin with difficulty. Change the fluid in the system in time.

- Bending or fracture of the tubes. For the lines of the power steering system, special hoses must be selected, since the pressure in them is very high.

- Pump

Power steering is a device that serves to lower the steering gear. They facilitate the work of the driver's hands when parking and turning. Thanks to the hydraulics, the car becomes so light that you can twist it with just one finger. And today we will devote a separate article to this mechanism in order to find out its structure and principle of operation.

What can they do?

Power steering not only reduces the effort applied by the driver to turn the steering wheel, but also absorbs all the shocks that are transmitted from the tires to the entire chassis when hitting a bump. This significantly reduces the load on all other suspension parts.

An interesting fact is that a car equipped with a power steering system does not enter a ditch at a sudden speed. At the same time, a car without hydraulic booster becomes uncontrollable if a tire on the drive axle suddenly deflates. Thus, the hydraulic booster system provides you with additional safety when driving.

How is this mechanism arranged?

Power steering includes the following mechanisms:

Principle of operation

If the vehicle is moving in a straight line, the power steering is inoperative. They are activated only after a certain rotation of the wheel. If the car drives straight, the fluid in the system circulates in a circle, that is, from the sediment it goes back to the reservoir.

Only after the driver has turned the steering wheel does the hydraulic booster begin to operate. At the same moment, the torsion bar is twisted, as a result of which the spool rotates relative to the distribution sleeve. After opening the channels, the liquid enters one of the openings of the power cylinder. What kind of cavity it will be depends on the direction of rotation. At the same time, liquid is drained from another hole into the tank. Thus, the piston of the cylinder ensures the movement of the steering rack. The last part transfers forces to the wheel, after which it turns.

If the hydraulic booster is activated in a parking lot or when turning in a confined space, that is, when the vehicle speed is low, it works with the greatest performance. The power of effort depends on the pump motor. It receives a signal from the ECU, thereby opening the system. Accordingly, with an increase in fluid pressure, a greater force is created to turn the wheel. Therefore, the driver almost never makes additional efforts to turn the steering wheel.

How much does power steering cost? The price of this device is about 20-25 thousand rubles.

Every modern car has a power steering. The pressure of the working fluid for the operation of the power steering is created by a special pump - about the purpose of the hydraulic booster pump, the types of pumps that exist today, their design and operation, and also about maintenance and repair, read the article.

General power steering device

In any modern car and wheeled tractor, there is always a system that greatly facilitates the work of the driver - power steering (GUR). Amplifier built directly into steering, allows the driver to spend less effort when turning the steering wheel, improves handling and safety vehicle in any conditions.

The power steering device depends on its type; at present, three main types of hydraulic boosters can be distinguished:

- Power steering with a separate steering mechanism and a power hydraulic element;

- Power steering with a combined steering mechanism and a power hydraulic element;

- Rack and pinion power steering, combined with steering gear rods.

The hydraulic booster with a separate steering mechanism and a power element includes a pump, a switchgear, a power hydraulic cylinder, a reservoir for working fluid, a piping system and some auxiliary elements. In this case, the power cylinder is connected to the steering gear or directly to the wheels, and minor changes are made to the regular steering.

The hydraulic booster with a combined steering mechanism and a power element includes a steering mechanism with an integrated switchgear and a hydraulic cylinder, a pump, a reservoir, pipelines and additional elements. As in the first case, the steering force is transmitted to the steering gear with the help of additional traction.

Rack and pinion power steering is a further development of hydraulic boosters with a combined steering mechanism and a power element. The rack includes transverse steering rods, and a gear-rack pair is used as a gearbox (from where this mechanism got its name). Typically, racks are used on front-wheel drive cars, although in last years these mechanisms are increasingly being installed on commercial trucks and vans.

In all these types of power steering, fundamentally the same pumps are used, which need to be discussed in more detail.

Purpose and place of the pump in the power steering system

The hydraulic booster system uses oil as a working fluid, which is supplied to the actuator under pressure. just what is needed to create a working oil pressure in the system.

The power steering pump is installed on the power unit of the vehicle, for which a special bracket or mating surface is provided. The pump is driven by the engine crankshaft, the drive can be one of two types:

- V-belt transmission;

- Gear transmission.

V-belt drive, in turn, is of three types:

- One V-belt;

- Dual V-belt;

- V-ribbed belt.

A drive with a single V-belt is rarely used today; it can be found on GAZelle, VAZ-2121, etc. cars. The double belt drive is more often used in domestic trucks. Poly V-belt is used on passenger cars, vans and commercial trucks.

The gear drive of the power steering pump is used on trucks. It is more complex, since the engine must initially be developed for a specific type of pump. The pump drive in this case is also carried out from the crankshaft, however, the torque is directly transmitted to the pump gear from one of the gears of the drive of the engine units.

Despite the variety of pumps, they all have a fundamentally the same device.

Types and design of pumps used in hydraulic boosters

At present, double-acting vane (vane or vane) pumps are most widely used (letters "L" or "Sh" are usually present in the marking of domestically produced pumps). Such pumps the best way work with a viscous incompressible fluid, have high performance and reliability, and at the same time have a fairly simple device.

The basis of the pump is made up of three components - a rotor with movable plates, a stator and a distribution disk. The rotor is inserted inside the oval hole of the stator, and the whole structure is mounted on a sealed housing or pump housing cover. On the opposite side, the rotor and stator are closed by a distribution plate with windows located in a special way. The rotor is mounted on a shaft, through bearings installed in the housing, outside the pump, the shaft ends with a pulley or gear. The package of the body, stator and cover is pulled together with four bolts.

The pump contains a number of additional components - several valves (bypass, safety or pressure), sensors, seals and o-rings, fittings, pipes, etc.

It should be noted that today there are two types of power steering pumps that differ in layout and placement of the oil tank:

- With a tank mounted on the pump;

- With a remote tank (placed in the engine compartment).

In trucks KAMAZ, GAZ, ZIL and others, power steering pumps integrated with a reservoir are widely used. But today, pumps with a remote tank are more common, due to the convenience of the layout of the units on the engine and in the engine compartment, as well as the convenience of servicing the hydraulic booster.

The principle of operation of the power steering pump

The vane pump works quite simply. The rotor, inserted into the stator with an oval hole, forms two closed crescent-shaped cavities, into which there are two windows - through one of them oil is supplied from the tank, and through the other it enters the system under pressure. The blades (gates) are installed in the rotor with a certain gap (without interference), so they can move freely along the grooves of the rotor up and down.

When the rotor rotates, the blades move out of their slots under the action of centrifugal force and abut against the stator, as a result of which a number of sealed cavities are formed between the blades. Since the stator has an oval shape, when the rotor rotates, the volume of the cavities is constantly changing - this is the basis for the principle of operation of the pump.

The oil supply window to the rotor is located in the area of the expansion of the stator cavity, here it is captured by the expanding cavity between two adjacent plates. The flow of oil into the cavity is ensured by their expansion - with an increase in volume, air rarefaction is formed, as a result of which the oil is sucked into the cavity, completely filling it. The same effect ensures the flow of new oil from the reservoir to the pump.

With further movement, the cavity with oil leaves the inlet window and becomes airtight. But soon a tapering section of the stator begins, on which the blades are pressed into the rotor and the volume of the cavity decreases. Since the cavity is sealed, the oil contracts and its pressure rises. At a certain moment, the cavity approaches the outlet port, and the pressurized oil escapes through it into the system. Some of the oil under pressure is fed into the grooves of the rotor blades, which ensures a more reliable pressing of the blades to the stator walls.

Since the hole in the stator has an oval shape, crescent-shaped cavities are formed on both sides of the rotor, and the processes described above occur in each of them. That is why pumps of this design are called double-acting pumps.

The oil is released from the pump through a calibrated orifice with a limited capacity. With an increase in the crankshaft speed, the performance of the power steering pump increases, however, all the oil does not have time to exit through the calibrated hole, it flows through the channel to the bypass valve, when the critical pressure is reached, the valve opens and directs the oil either to the pump inlet or to the tank. This prevents an uncontrolled increase in pressure in the system by high revs motor.

However, the pressure can increase not only due to an increase in the frequency of the engine, but also for other reasons - due to various blockages or breakdowns. With an excessive increase in pressure in the pump, a safety valve opens, which also diverts the working fluid to the pump inlet or reservoir. Modern pumps often use sensors and electric actuators to control valves.

Issues of maintenance and repair of power steering pumps

Requires minimal maintenance - it is necessary to monitor the appearance of leaks, fastening the pump and tensioning its belt. Typically, the pump serves several hundred thousand kilometers and requires intervention only when malfunctions occur.

Most often, the following malfunctions occur in the pump: wear of bearings, rotor and blades, sticking or complete loss of valve performance, wear of seals. All this is manifested by a deterioration in the operation of the amplifier, and the wear of parts gives itself out as knocks and increased noise. It is also harmful for the pump to lower the oil level and air the system, this is also manifested by increased noise.

A faulty power steering pump, especially with worn parts, is easiest to replace as an assembly, and most modern pumps do not even provide for disassembly and repair. After replacing the pump, air must be removed from the system, and after a simple adjustment, the power steering starts to work normally.

In this article, I have decided to give short description power steering devices ShNKF 453461.100, ShNKF453461.120 and answer some questions related to its operation. All data are taken from the official publication on the operation of the power steering, developed by RUPP "Borisov Plant" Avtogidrousilitel ", well, and some of my experience in repairing and configuring this device.

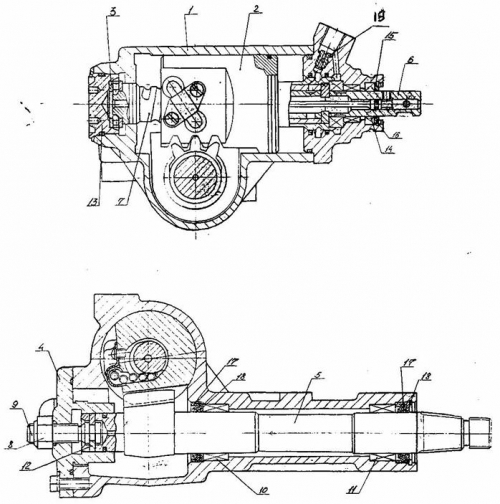

Power steering device

Brief description of the design of steering mechanisms with hydraulic booster ShNKF 453461.100, ShNKF453461.120

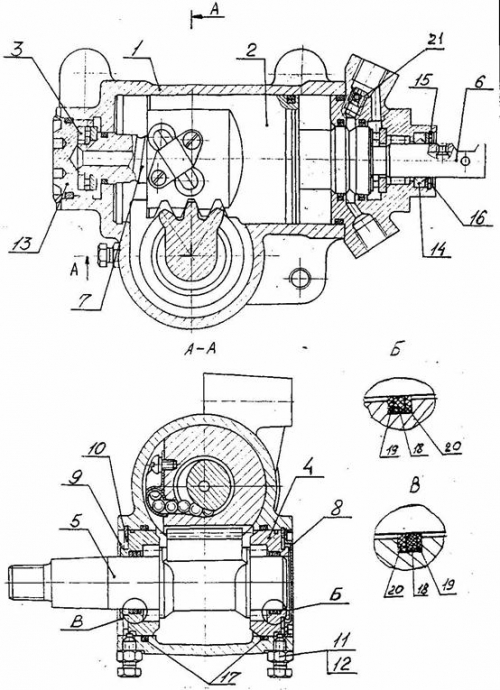

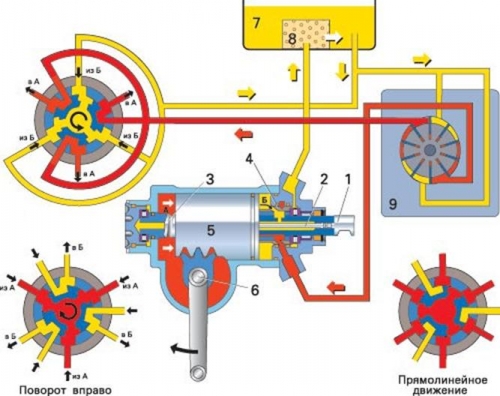

Power steering mechanisms are made according to an integrated circuit, that is, a hydraulic distributor and a power cylinder are placed in the same housing with the steering mechanism (Fig. 1, Fig. 2).

Steering gear type: screw-ball nut-toothed rack-three-tooth sector. The toothed rack is made integral with the piston and ball nut of the screw gear. The steering gear screw interacting with the ball nut is mounted on two thrust bearings, one of which is located in the steering gear housing, and the second in the distributor housing. The bearing preload is adjusted with an adjusting nut located in the crankcase. After adjustment, the nut band is jammed into the grooves.

Hydraulic distributor of mechanisms - tangential, rotary type with a centering element in the form of a torsion bar.

The spool shaft of the distributor has one end with working hydraulic elements placed in the axial hole of the steering gear screw, and the other end rests on a radial roller bearing in the distributor housing.

The spool shaft and the screw are interconnected by a torsion bar, the angle of twist of which is limited by segment stops installed between the spool shaft and the screw. Through the segment stops, a mechanical connection is made between the spool shaft and the propeller when turning the car with an idle hydraulic booster. The hydraulic neutral position of the spool shaft is set during the assembly and acceptance tests of the distributor and is fixed with a pin. In operation, disassembly and adjustment is not allowed.

In the steering gear SHNKF 453461.100, a three-tooth sector with a shaft is installed in the steering gear housing on two roller radial needle single-row bearings. Gearing adjustment in order to eliminate the gap is carried out by unscrewing the adjusting screw installed in the shaft sector and the side cover of the crankcase. After adjustment, the screw is fixed with a lock nut.

In the steering gear SHNKF 453461.120, a three-tooth sector with a shaft is installed in the steering gear housing on two roller radial bearings in eccentric bushings. Adjustment of the gearing in order to eliminate the gap is carried out by simultaneously turning the eccentric bushings from the initial position clockwise, as viewed from the side of the splined end of the shaft sector.

After adjustment, the eccentric bushings are fixed with locking bolts located on the steering gear housing by deforming the locking shoulder of the bushing with each bolt, and the bolts themselves are locked with locknuts.

Rice. 1. Steering gear SHNKF 453461.100

1 - crankcase; 2 - piston-rail; 3 - roller thrust bearing; 4 - side

lid; 5 - shaft sector; 6 - input shaft; 7 - screw; 8 - locknut; 9 - adjusting screw

level; 10.11 - radial roller bearings; 12 - adjusting washer

naya; 13 - adjusting nut; 14 - cuff; 15 - protective cover; 16 - ring

shut-off; 17 - stuffing box; 18 - cuff amplifier; 19 - check valve

Rice. 2. Steering gear: SHNKF 453461.120

1 - crankcase; 2 - piston-rail; 3 - roller thrust bearing; 4 - shaft-sector support;

5 - shaft-sector; 6-input shaft; 7 - screw; 8 and 9 - protective covers; 10 - retaining ring;

11 - locking bolt; 12 - counter nut; 13 - adjusting nut; 14 - cuff; 15 - protective cover; 16 - locking ring; I7 - sealing ring; 18 - seal ring

thread; 19 - protective ring; 20 - protective ring; 21 - check valve

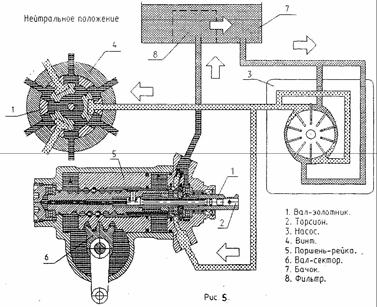

Brief description of the power steering pump ShNKF 453471.100 and its modifications.

The power steering pump is designed to pressurize the working fluid into the power steering system. The pump type is vane type with built-in flow and maximum pressure valves. The pump consists of a housing 1 (Fig. 3), a roller 7, a pulley 8, a set of workers and a cover with valves 3. Suction and discharge pipelines are connected to the cover. Depending on the engine used in the vehicles, the pumps are equipped with various pulleys (single-stranded wedge or poly-wedge).

The operating speed of the input shaft must be:

within 600-6000 rpm,

The minimum volume flow at 600±20 rpm and a pressure of 5.0+0.3 MPa (50+3 kgf/cm2) must be at least 4 l/min,

The nominal volumetric flow of pumps at a pressure of 5.0 + 0.3 MPa (50 + 3 kgf / cm2) should be:

at a speed of 800 rpm - 4.8 l/min, not less

at a speed of 2000 rpm - 7.3 l/min, no more.

The safety valve actuation pressure must be within 8.5-9.5 MPa (85-95 kgf/cm2) for pumps of the ShNKF453471.100 series, within 11.0-11.5 MPa (110-115 kgf/cm2) for pumps of the ShNKF453471.115 series ) at a pump shaft speed of 800+_20 rpm.

Rice. 3. Power steering pump SHNKF 453471.100

1 - pump housing; 2 -stator; 3 - pump cover with valves; 4 - screw; 5 - pin; 6 - radial ball bearing; 7 - roller; 8 - pulley; -9 - bypass valve; 10 - adjusting washers; 11 - plug plug; 12 - safety valve seat; 13 - bypass valve spring; 14 - safety valve; 15 - rotor

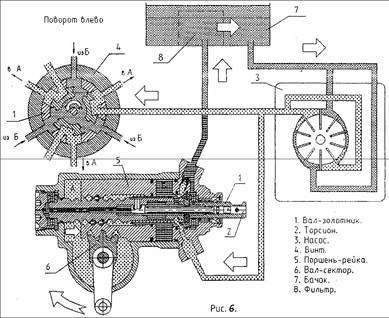

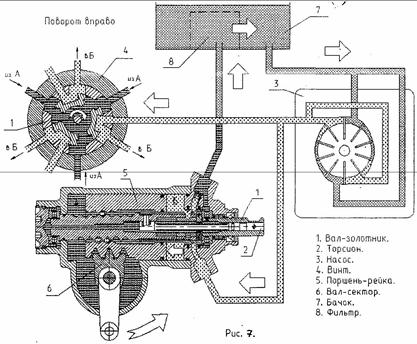

The operation of the power steering system.

When moving in a straight line, the spool shaft 1 (Fig. 5) of the steering mechanism is held in a neutral position by means of a torsion bar 2. The discharge and drain lines, as well as the working cavities A and B of the amplifier hydraulic cylinder are interconnected. The oil freely passes from the pump 3 through the hydraulic distributor in the cavity A and B, and returns through the drain line to the tank 7 of the hydraulic system. At the same time, in the neutral position, the spool shaft ensures the equality of pressures in the working cavities A and B of the booster hydraulic cylinder. When the steering wheel is turned, the working fluid supplied under pressure from the pump passes through the hydraulic distributor, which directs it to the corresponding cavity (into cavity A, in Fig. 6; into cavity 5, in Fig. 7) of the hydraulic cylinder. Under the action of the pressure of the working fluid, the piston-rack 5 moves and the shaft-sector b of the steering mechanism with a bipod and then the steered wheels rotate. At the same time, from the opposite cavity (from cavity B, Fig. 6; from cavity A, Fig. 7), the liquid is displaced by the piston rail into the drain line, and then the tank enters, passes through the filter element and enters the pump through the suction line.

I will also give a color diagram of the operation of the hydraulic booster.

It's all about the device. I can, of course, still breed theories, but I think it’s enough to have an idea about the principle of operation of the hydraulic booster.

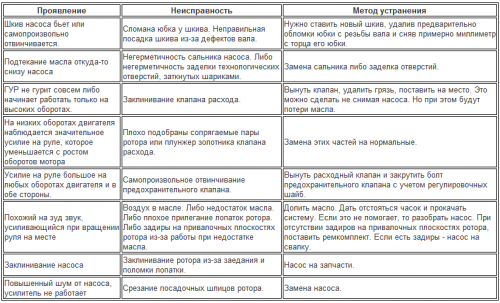

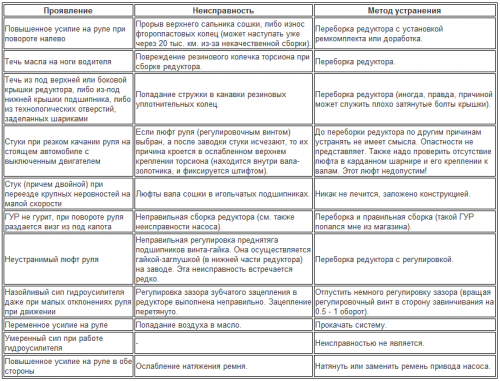

Now let's look at some typical power steering malfunctions and how they manifest themselves.

Pump malfunctions

Reducer malfunctions

These faults have been identified in practice. They relate mainly to the power steering units themselves. Not all of these malfunctions can be eliminated in garage conditions, especially if there is not enough practice, it is better to contact the service.

Now let's touch on the oils used in the power steering system and how to replace them.

Working fluids (oils) used in the power steering system,

should be the following:

basic - oil grade "R" TU 38.1011282;

substitutes (according to ISO-L-HM class 22):

- DIN 51524 part 2 HPL oils;

- AF NOR NFE 48600 HM category;

- Denison HF-2 type AGIP OSO SD;

- ATF (dexron) nach ZF-oelliste TE-ML09;

- oil grade "A" TU 38.1011282.

However, I do not recommend using oils of type “P” TU 38.1011282 and “A” TU 38.1011282, because 99% is fake. Real oil "P" is dark brown to brownish yellow (but dark in color anyway), they sell spindles in the store ( yellow color), and it spoils the power steering seals. You should not think that draining the oil from the pump and reservoir will make a complete oil change. Even if part of the oil is expelled from the gearbox, at least 250 ml will remain in it, which can be drained only by disassembling the gearbox. And since 250 ml. - this is almost 20% of the total volume, then you should never top up the spindle. Even if you later change the oil, the remains of the spindle will do their dirty work.

Additionally, you can drive out some of the oil remaining in the gearbox by turning the wheels in both directions several times with the fittings of the supply and return hoses twisted. But this does not provide a complete drain of the oil.

Domestic oil poured at the factory is not so bad, when disassembling such gearboxes, all rubber bands retain elasticity and elasticity, and only in those to which fake P or A grade oils were added are distinguished by hardened rubber bands.

For hydraulic systems, the most acceptable is mineral oil, but real (not burnt) mineral hydraulic oil is difficult to get, so the most common oil suitable for replacement is DEXRON II - p / synthetics and DEXRON III - synthetics, it is better to give preference to the first. Both oils are red.

Now how to change the oil?

The most correct way would be to unscrew the return hose from expansion tank and lower its end into some container. And connect the inlet hose going to the hydraulic pump to a container with oil, start the engine and drive the oil through the entire system, thereby guaranteeing a complete oil change, but this method is too wasteful, so we proceed as follows:

We hang out the front wheels, we will need this for subsequent pumping and forcing out excess old oil. We unscrew the fitting of the high pressure hose going to the pump and drain the oil into the container. Through the return line and the pump, the oil will flow out of the reservoir and partially out of the gearbox (everything will come out of the pump). Now we slowly turn the wheels in both directions several times, let the oil drain. We put the fitting in place and pour oil into the tank, wait until the level stops dropping, start the engine for a while and run the oil through the system, then repeat the operation - unscrew the drain ... etc. (i.e. we are essentially flushing the system).

Now the final operation:

- Set the steering wheel to the straight ahead position,

- Remove the reservoir cap of the power steering pump and fill in clean oil slightly above the level of the inlet filter screen. After 3...5 minutes after pouring, check the oil level in the tank and, if necessary, top up to the grid level,

- Start the engine and let it run without turning the steering wheel for 10...15 s. In this case, if the level drops, it is necessary to add oil to the tank to the level of the grid. Then on idling of the engine, smoothly turn the steering wheel from the position of movement in a straight line to each extreme position and back, while monitoring and adding oil to the tank to the level of the filler filter screen. Continuing to smoothly turn the steered wheels from end to end, make sure that the oil level in the reservoir remains unchanged.

It is not allowed to hold the steering wheel in extreme positions.

We stop the engine. Now we turn the wheels again to the extreme left position in the direction of travel. There is an air bleed valve on the gearbox cover. We put a transparent tube on its fitting to see the outgoing air and turn it off a little. We turn the wheels smoothly in the opposite direction with the fitting open, air should flow. In the extreme right position, close the valve and return the wheels to the left position. We unscrew the valve and again the wheels to the right. In principle, in this way the air is almost completely expelled in 3-4 times. The rest of it will then come out through the tank, which will be visible from the small bubbles in the tank, but the oil should not foam.

Excessive foaming indicates leaks in the hydraulic system connections.

In a fully filled hydraulic system, the oil in the reservoir of the hydraulic booster pump should be at the level of the inlet filter screen.

Now everyone is ready to go.