Priora maintenance regulations. Weaknesses and features of repairing Lada Priora

Modern Lada model

A car is not only a means of transportation, but also a complex mechanism. Each of vehicles has its own strengths and weaknesses. In order to understand how reliable it is, it is necessary first of all to analyze each of the machine components.

Lada Priora is considered a fairly “hardy”, stable car, but it also has its weak points. The owner of a car of this brand must be aware of them so that, if necessary, they can repair the Priora on their own. Moreover, the troubleshooting instructions are not the most complicated.

The most common problems with the Lada Priora engine

One of the most common malfunctions that leads to unplanned repairs and visits to auto repair shops is the failure of the timing belt support bearing or water pump device. These breakdowns are fairly easy to fix, although repairs and maintenance are not cheap. Since separately support bearings are not found on sale, you have to purchase a complete timing belt kit. According to the rules for safe movement on the roads and operation of a Lada Priora car, the timing belt is replaced every 120 thousand km. However, failure of the bearing and pump itself, as a rule, leads to belt breakage, therefore, its complete replacement may be required much earlier than the time prescribed by the operating instructions.

It is rare, but nevertheless possible, to repair a Lada Priora related to the vehicle's control system, as well as its suspension. In the latter case, the rack support may need to be replaced. One of the reasons for the failure of strut bearings may be poor sealing and, as a result, dust and dirt entering the bearing assemblies. It is quite easy to identify this breakdown yourself - when turning the steering wheel all the way, Priora Club drivers can hear clicks.

The weak point of the Lada Priora is the front hubs. They are quite easily deformed when car wheels get into even shallow holes.

When repairing a Lada Priora is possible with your own hands

If the car's mileage is more than 100 thousand km, the ball joints may become unusable. Process them self-replacement does not require special skills. Problems with the heating system can arise due to a malfunction of the heater dampers or when the motor or gearbox device fails.

Replacing shock absorbers and suspension springs may be necessary much earlier than the stated warranty mileage of 200 thousand km in the event that the operation of the car does not meet the requirements domestic manufacturer. The presence of caps on the rear hubs is a necessary condition. If they are absent, dirt, dust, and water will inevitably get into the assembly, which will certainly lead to breakdown of the entire assembly.

Under the hood of the car

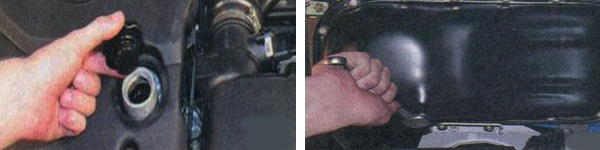

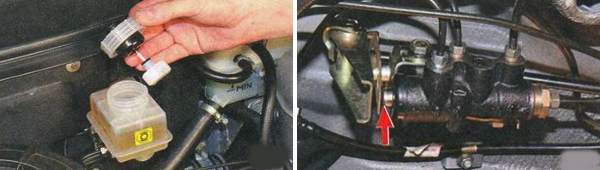

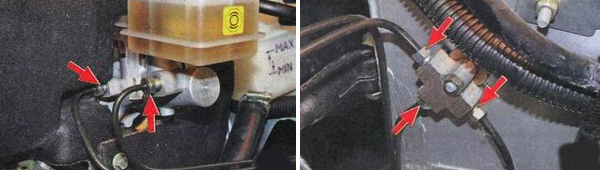

If an unknown noise appears while driving, first check how securely the power steering reservoir is fastened. It may not have been screwed securely enough during factory assembly.

The appearance of corrosion on a car cannot be attributed to the disadvantages of this particular model, because under the influence weather conditions Any car sooner or later begins to rust. The weakest points are the attachment points of the decorative overlays. To avoid corrosion, Priora Club members advise periodically treating the surfaces of your vehicle with special anti-corrosion additives.

VAZ Priora with 1.6 liter engines, eight-valve and sixteen-valve. The schedule of all maintenance work is given in accordance with the service book. The prices of replacement parts for each maintenance are also indicated (in US dollars at the date of writing). Prices are for Moscow. Prices for oil and liquids are not given due to the many differences between different manufacturers. The cost of work is shown in the range of offers from Moscow service stations. It is also necessary to keep in mind that, under severe operating conditions, it is recommended to change motor oil with filter every 10,000 km.

Work and checks during all maintenance

- and engine oil. Oil with specification according to API SM, SN is used. selected depending on the region of operation. Oil volume 3.5 l. Number oil filter 21080-1012005-09. The cost of the original filter is from $0.89 to $1.22. Prices for works range from $7.08 to $18.

- Tighten the transmission mounts.

- Tighten the fastenings in the rear and front suspension.

- Check the absence of knocking in the engine, the level of exhaust toxicity, .

- Check for knocking noises in the gearbox, clutch and wheel drives. As well as gearbox control drives and gear shifting.

- Check the tightness and condition of the brake system and the effectiveness of the brakes on all wheels.

- Check the steering column fastening and the serviceability of the EUR.

Work during maintenance 1 (mileage 2500 - 3000 km)

Checks during the first maintenance

- tightness of the cooling system;

- tightness and integrity of the power system;

- exhaust toxicity level;

- gearbox tightness;

- tightness and condition of the brake system;

- condition of the anthers and lubrication of the front wheel brake guide pins;

- adjusting the handbrake;

List of works during maintenance 2 (mileage 14500 - 15000 km or 1 year)

- Works and checks during all maintenance.

Checks during the second maintenance

- coolant level;

- gearbox oil level;

- wear of the front brake pads.

List of works during maintenance 3 (mileage 29,500 - 30,000 km or 2 years)

- Works and checks during all maintenance.

- . Code. Prices 0.76$ - 1.35$.

- . Part code 21230-1117010-02. Prices from $4.60 to $19.57.

- . Code 21120-1109080-06. Cost from $3.36.

Checks during the third maintenance

- coolant level;

- gearbox oil level;

- gearbox tightness;

- condition of wheel drives and jet thrust;

- condition of the front and rear suspensions;

- checking and adjusting the angles of the front wheels;

- condition of tires, wheel rims, their balancing, and also rearranged according to the diagram;

- the condition of the steering rods and boots of the steering mechanism, as well as the play of the steering wheel;

- brake fluid level and level indicator;

- wear of rear brake pads;

- tightness of the working brake cylinders and adjustment of the handbrake;

- performance of the “sorcerer”.

List of works during maintenance 4 (mileage 44500 - 45000 km or 3 years)

- Works and checks during all maintenance.

- . 16-valve belt 21126-1006040-00, prices $11.16 - $32.82. The price for work is from $15.

- . The fluid used is DOT-3 or . System volume 0.45 l. Cost of work starts from $5.

Checks during the fourth maintenance

- All maintenance checks 2.

- Check the vacuum brake booster.

List of works during maintenance 5 (mileage 59,500 - 60,000 km or 4 years)

- Works and checks during all maintenance.

- All maintenance checks 3.

List of works during maintenance 6 (mileage 74,500 - 75,000 km or 5 years)

- Works and checks during all maintenance.

- Tighten the engine fastenings.

- . Volume 7.84 l. The cost of work is from $10.5.

- . Part code. Prices: $29.57 - $35.07.

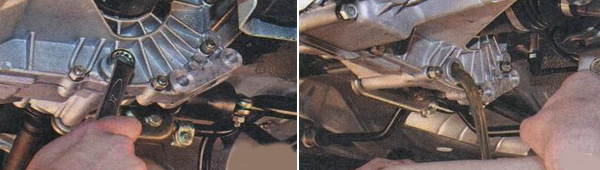

- . API GL-4 group. Volume 3.1 l. The cost of work starts from $5.

Checks during the sixth maintenance

- condition of wheel drives and jet thrust;

- condition of the front and rear suspensions;

- the condition of the steering rods and boots of the steering mechanism, as well as the play of the steering wheel;

- brake fluid level and level indicator;

- wear of the front brake pads;

List of works during maintenance 7 (mileage 89,500 - 90,000 km or 6 years)

- Works and checks during all maintenance.

- Replace brake fluid.

Checks during the seventh maintenance

- all maintenance checks 3;

- check the vacuum brake booster.

List of works during maintenance 8 (mileage 104,500 - 105,000 km or 7 years)

- Works and checks during all maintenance.

Checks during the eighth maintenance

- all maintenance checks 6;

- coolant level;

- gearbox oil level;

How much does Lada Priora maintenance cost?

The cost of basic diagnostics during the next maintenance is about 3,000 rubles ($45.4). Checking the condition and levels of liquids up to 1000 rubles. (~$15). Let's add the cost of oil (minimum $7.11 for 4 liters), filter on average $1 and replacement cost from $7, we get ~60$. At the third maintenance, fuel, air and spark plug filters are added to the amount of the first in the amount of about $16 (along with the cost of replacing them). The amount of the third one is already about $66. The fourth maintenance can cost $57. And the most expensive sixth maintenance, plus ~$100 to the cost of the first maintenance.

Like all domestic cars, Lada Priora has its drawbacks. During the release of the model, a list of the most frequent breakdowns and weak points of this machine was formed. For Lada Priora, repairs of engine spare parts and electrical equipment are common occurrences. There are also problems with the suspension struts and interior plastic.

In case of serious breakdowns that are beyond your competence, you need to undergo diagnostics at a service station. But if you are sure that you are able to identify a certain, not too serious breakdown, you can cope on your own. on your own will help you complete the operation and repair manual for the VAZ 2170.

Engine problems

When a driver undergoes Priora maintenance, service station workers often discover faults in the engine systems. The most common causes of engine failure are as follows.

- Problems with the timing belt.

- Failure of fuel pump parts.

- Crankshaft position sensor failure.

Signs: loss of power, engine stability. The repair manual prescribes how to replace the timing belt, repair the fuel pump, and replace the crankshaft position sensor. Car repairs are performed with the ignition off.

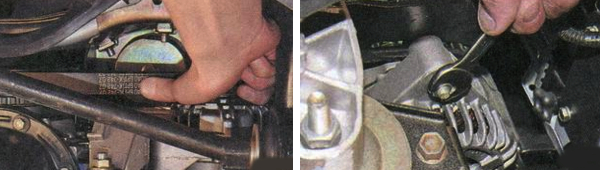

First you need to remove the right engine protective shield, release the latch that holds the engine control system wiring harness block. Then you should disconnect the crankshaft position sensor from this block. The sensor is dismantled using a 10mm wrench. Unscrew the mounting bolt.

You need to check not only the sensor itself, but also its entire circuit. We do not turn on the ignition, the crankshaft is motionless. We connect one multimeter probe to the terminal of the block harness, the other to ground. The voltage on the tester should be approximately 2.5 V. Repeat the procedure with the other terminal of the harness. If the voltage is normal, you need to check the circuit for an open or short circuit: the section between harness pin 1 and controller pin 34, as well as the wire that connects harness pin 2 and controller pin 15.

If the voltage and circuit are OK, the controller may have failed. We test the sensor itself using a multimeter. Normal operation of the sensor occurs with a resistance of 550–570 Ohms. And in AC mode, when the steel rod is brought to the end of the sensor, a voltage surge should occur. Then the sensor is normal. If none of the conditions are met, replace the sensor and install it back on the oil pump cover.

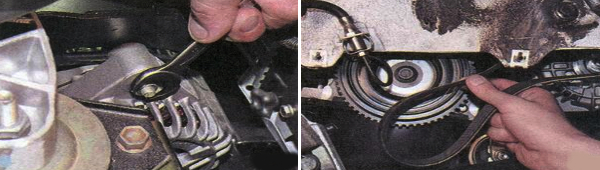

Caring for the timing belt involves replacing it after 200 thousand kilometers. Checking is recommended every 45,000 km. After all, a broken belt, “licking” of teeth, the presence of folds, cracks, and fiber breaks lead to a violation of the phases of the camshaft and crankshaft. Consequences: jamming of pistons, valves, connecting rods. The presence of oil on the belt is also unacceptable. If such breakdowns are detected, we replace the timing belt. Repair and maintenance of the belt is carried out in accordance with the instruction manual. The main thing you need to know: before removing the belt, you need to set the shafts to the TDC (top dead center) position of the piston.

To check the pressure in the fuel rail, which depends on the fuel pump and filter, you will need a pressure gauge. You need to insert it instead of the spool, which is located under the fuel rail fitting. With the ignition on, take readings from the pressure gauge. The value should be between 3.6–4 bar.

We check the serviceability of the fuel pump by ear. If the pump makes unusual sounds or the pressure is not as specified, the parts must be replaced. The replacement process is described in the operating and repair instructions.

Sometimes the Priora electrician fails

Electrical equipment often suffers from breakdowns:

- electric power steering;

- wiper drive;

- headlight lamps.

At the first stages of Lada Priora sales, problems arose with a new function - electric power steering. This was a trial step for AvtoVAZ, and it is logical that there were some disruptions. Jerks were observed when the steering wheel rotated, as well as jamming and stiff movement. The electrical diagram provided in the owner's manual helps to trace the steering drive circuit and identify faults. Sometimes the problem was solved by simply cleaning the contacts and strengthening the wiring. But often the breakdowns were much more serious, and only the service station workers could solve them.

Over time, the plant developed optimal assembly technology. Therefore, problems with the amplifier occur much less frequently. If the drive performance deteriorates, open the “Electrical equipment” section of the VAZ operating manual. We check the entire drive circuit for continuity and short circuit, and also clean the contacts.

On already “middle-aged” Priors, problems with the ignition coil can be traced. Also, over time, malfunctions in the operation of the windshield wiper drive occur, and headlight bulbs burn out. You can repair these parts yourself, following the instructions in the manual.

The standard battery on the Priora is not entirely successful. There are often complaints that the battery lasts a year and a half. Normal service life is up to three years. The battery on the Lada is a non-separable type, so you only have to replace it.

Malfunctions in the suspension and interior

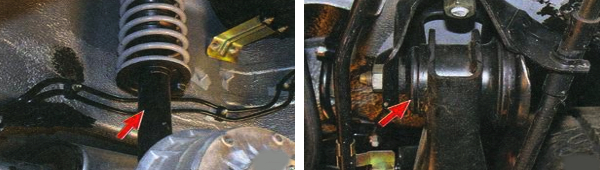

The front and rear suspension of the Lada Priora is equipped with hydraulic shock absorbers. The hydraulic fluid of the struts often begins to leak. In addition, other failures are possible.

| Problems | Your actions |

| A frequent malfunction of the Lada is a violation of the tightness of the hydraulic cylinders of the strut shock absorber. | In this case, the stand may need to be replaced. The instructions describe how to remove the stand. You need to disconnect it from the fastenings under the hood, and on the other hand, disconnect the fastenings of the steering tip and steering cam. We remove the strut from the spring with a special puller and replace it with a new one. |

| A separate problem: the CV joint (angular velocity control joint) crunches. | This kind of malfunction happens even on new Priors. Drivers often note that external visibility does not help identify a defect. In this case, you should contact a service station. |

| The remaining problem areas of the Lada suspension are: wheel bearing, anti-roll bar. | You can replace them yourself. Detailed instructions are described in section 7 “Chassis”. See the subsections “Replacing stabilizer parts”, “Replacing the bearing”. |

Often, after a certain mileage, the plastic used to trim the interior begins to rattle, knock, and creak. In this case, there can only be one repair - soundproofing the Lada's interior. In this case, four main materials are used: vibration insulation, noise absorber, sound reflector, squeak suppressor.

Power unit of Lada Priora: studying design and resource features

Power unit of Lada Priora: studying design and resource features

The main sign indicating the need for inspection technical condition vacuum booster brakes on a Lada Priora car consists of a significant increase in the pressure on the brake pedal. In addition to the amplifier itself, it is necessary to check the tightness of the vacuum hoses. Prepare a standard set of tools and a rubber bulb. Then do the following sequence of actions: First of all, you need to create pressure in the system. For this […]

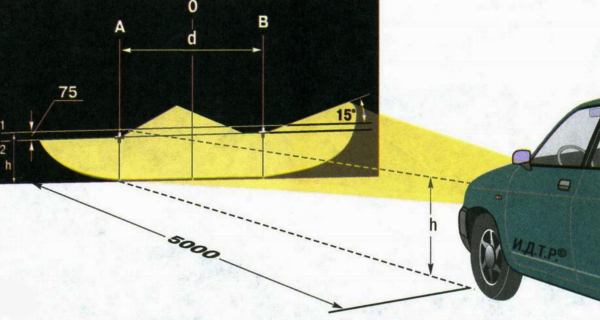

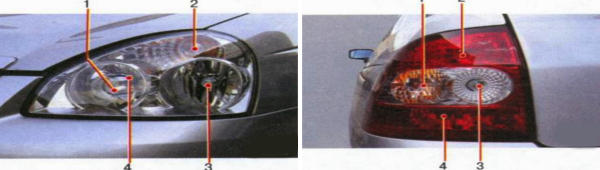

Adjusting the headlights on a Lada Priora car is carried out in cases where the light from the headlights no longer provides the required visibility of the roadway. Before proceeding with the adjustment, it is necessary to prepare the car: first of all, check the tire pressure and, if necessary, bring it to normal; the adjustment is carried out with full equipment, that is, a full fuel tank, a spare wheel, a standard […]

Replace the alternator drive belt on a Lada Priora car if it is damaged, broken, or according to the technical inspection card every 60 thousand kilometers. To perform repair work prepare a standard set of tools, and then do the following sequence of actions: Using a thirteen-size wrench, loosen the nut securing the generator to the adjusting plate. Next, use a ten key to turn out the adjusting [...]

An oil change on a Lada Priora car is performed together with a filter every 15 thousand kilometers. If the car is used in difficult conditions, dusty, it is recommended to replace it every 10 thousand km. It is more convenient to perform these works on a warm engine, when the oil has good fluidity and, as a result, drains better from the walls of the block. If you plan to change the brand of oil used, [...]

During operation, the crankcase ventilation system on the Lada Priora becomes clogged. The main reason for this is tarry deposits from crankcase gases, which impede circulation. The manufacturer recommends cleaning the system every 60 thousand km. To carry out repair work, prepare a standard set of tools, and then perform the following sequence of actions: First of all, we carry out preparatory work. […]

The coolant on a Lada Priora car is replaced every 75 thousand km according to the technical inspection card. Also, replacement should be made if there is a suspicion of mixing with water or when the liquid has changed its main color to reddish or dark, which indicates a loss of its basic properties. The manufacturer recommends replacing every 40 thousand kilometers [...]

The oil change in the gearbox on a Lada Priora car is performed every 75 thousand kilometers or once every 5 years. It is recommended to carry out this work within 15 minutes after stopping the car, when the oil is still hot and, as a result, has better fluidity. To carry out repairs, prepare a standard set of tools, new gear oil, container for draining [...]

Fluid replacement work brake system on a Lada Priora car, they are carried out according to the technical inspection card or every 45 thousand kilometers. Brake fluid is hygroscopic in its properties, which means that during operation it absorbs moisture and, as a result, loses its basic properties. To perform repair work, you will need the help of an assistant, a standard set of tools, a special wrench for fittings […]

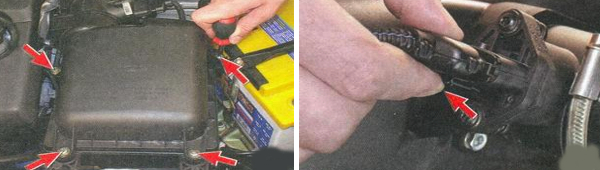

The manufacturer recommends replacing the air filter element on a Lada Priora car every 30 thousand kilometers. Depending on the operating conditions, these works are carried out more often. Also, during operation, do not forget to blow it with compressed air. To carry out repair work, prepare a standard set of tools and perform the following sequence of actions: Open the hood, then disconnect […]

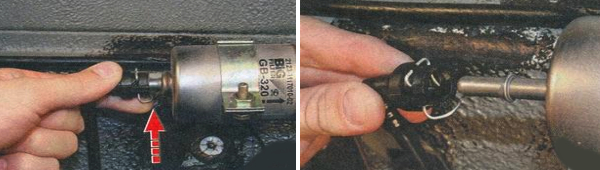

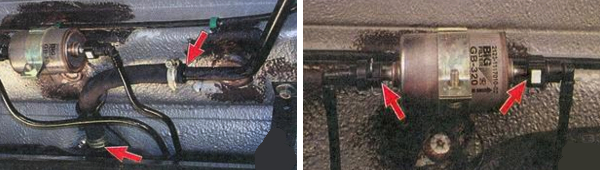

The manufacturer recommends replacement fuel filter on a Lada Priora car every 30,000 t.km. Of course, the need for replacement also depends on the quality of the fuel used. The main signs indicating the need for this work are the appearance of interruptions in engine operation and difficult starting. To carry out repair work, prepare a standard set of tools. Then do the following [...]

The filter of the ventilation and heating system of the interior of the Lada Priora car must be replaced according to the technical inspection card every 15 thousand km, but as practice has shown, it is more advisable to change it once a year, and under more severe operating conditions, that is, in rural areas and off-road, it must be changed twice a year or at least cleaned in a timely manner. […]

During the operation of a Lada Priora car, it is necessary to carry out a routine inspection of the spark plugs, adjust them and, if necessary, replace them. According to the manufacturer's recommendations, spark plugs are replaced every 30,000 km. To carry out repair work, prepare a standard set of tools; you will also need a special probe to check the gap between the electrodes of the spark plugs. Then do the following sequence [...]

Checking and subsequent adjustment of the parking brake drive on a Lada Priora car is carried out if there is a suspicion of deterioration in the operation of the handbrake when it stops holding the car on a slope. In addition, the inspection is carried out every 30 thousand kilometers according to the technical inspection card. As a rule, the cause of this can be either wear on the rear brake pads or a weakening of the drive cable. Normal […]

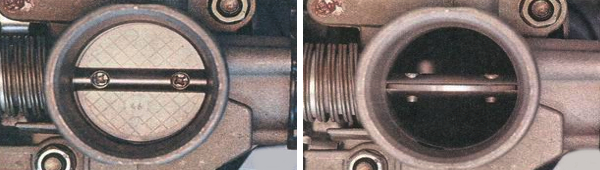

Drive adjustment throttle valve on a Lada Priora car, it is carried out according to the technical inspection card, or if there is a suspicion of deterioration in the starting and operation of the engine at different speeds. To carry out repair work, prepare a standard set of tools. Then perform the following sequence of actions: Open the hood and remove the decorative trim of the engine by unscrewing the screws securing it to the body. Next from [...]

On a Lada Priora car, the clutch release cable is equipped with a ratcheting mechanism and is free of backlash, which means theoretically its adjustment is not required. But the manufacturer gives recommendations for monitoring the travel of the clutch pedal and the accompanying clarity of gear shifting, and it is for these reasons that during each scheduled technical inspection, the drive is monitored and, if necessary, adjusted. […]

Cleaning the body drainage holes on a Lada Priora car must be done once a year. The purpose of this event is to timely clean the holes to prevent the accumulation of moisture in the hidden cavities of the body, which in the future can lead to the destruction of the metal and subsequent repair of individual body fragments. If the vehicle is frequently used on country roads, this work must be […]

External lighting on a Lada Priora is checked before each trip. These works are aimed at timely elimination of breakdowns that directly affect safety traffic. Perform the following sequence of actions: First of all, we check the functionality of the headlight lamps. Turning on each circuit one by one, we check: high and low beam headlight lamps (H1 55W are used), front turn signal lamps […]

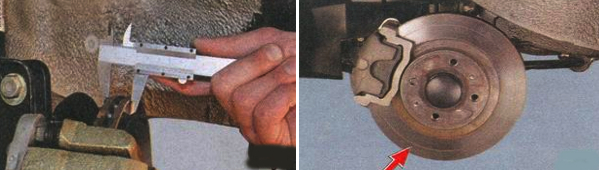

To carry out a preventive check of the wheels on a Lada Priora car, prepare a standard set of tools, a tire pressure gauge, a wheel wrench and a caliper. Then do the following sequence of actions: First of all, you need to check the tire pressure. To do this, unscrew the nipple caps and install the pressure gauge, pressing it lightly, thereby opening the spool button. If the pressure […]

Checking the tension of the alternator belt on a Lada Priora car is carried out according to the technical inspection card or every 15,000 km. The main sign indicating the need to check the belt tension is that the battery is poorly charged when the engine is running. To carry out repair work, prepare a standard set of tools, and then perform the following sequence of actions: Check the tension with your thumb, […]

Periodically, during the operation of the Lada Priora car, it is necessary to check the technical condition of the front suspension parts. These works are aimed at timely detection of malfunctions and subsequent elimination of found defects. To carry out repair work, prepare a standard set of tools, drive the car onto an inspection hole, overpass or lifts. Then perform the following sequence of actions: First of all, we carry out an inspection and [...]

If the timing belt on a Lada Priora is not adjusted in time, it can lead to engine damage. A weakened belt wears out quickly, and it is also possible for it to jump over the teeth, which leads to a failure of the valve timing and, as a consequence, deterioration in engine performance or the impossibility of starting it altogether. To adjust the belt tension, prepare a standard set of tools and a small hexagon […]

The technical condition of the rear suspension parts on a Lada Priora car is checked according to the technical inspection card, and preferably once a year, although with the quality of the current spare parts it is possible more often, it will not be superfluous. The main goal of this event is to timely identify faults and subsequently eliminate the defects found. To carry out repair work, prepare a standard set of tools [...]

Periodically during operation of the Lada Priora car, it is necessary to check the degree of wear of the brake pads and brake discs on the front and rear wheels. To perform repair work, prepare a standard set of tools, a caliper. Then perform the following sequence of actions: For the convenience of carrying out repair work, the car must be placed on lifts. Or you will have to alternately lift the front and back. […]

Checking the tightness of the hydraulic brake drive on a Lada Priora car is carried out according to the technical inspection card or every 45 thousand kilometers. At the same time, all rubber elements of the system must be replaced without fail, regardless of condition, every 100,000 km, which approximately corresponds to 7 years of vehicle operation. The main goal of this work is to timely identify [...]

Checking the tightness of the cooling system, pipes and radiator on a Lada Priora car is carried out every time there is a suspicion of a coolant leak. The check is also carried out according to the technical inspection card or every 75 thousand km. To carry out repair work, prepare coolant, sealant, new clamps in case you need to replace failed elements, you will also need […]

Checking the tightness of the fuel line on a Lada Priora car is carried out when there is a suspicion of a fuel leak, or according to the technical inspection card for preventive purposes. The main purpose of this work is aimed at checking the quality of fastening of fuel pipes, their connections, and external condition. To perform repair work, prepare a standard set of tools and perform the following sequence of actions: For ease of work, the car […]

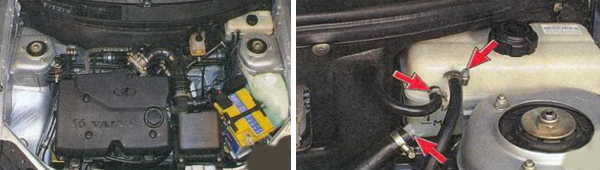

Washer reservoir windshield on a Lada Priora car it is located in the engine compartment; it is filled with a special non-freezing liquid. Periodically during vehicle operation, it is necessary to monitor the level and, if necessary, top up the fluid. The manufacturer does not recommend using ordinary water in the system, since failure to replace it in a timely manner can lead to severe frosts may damage the tubes and [...]

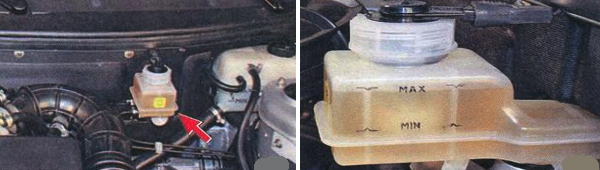

According to the operating rules of any car, including the Lada Priora (VAZ 2170), the brake fluid level in the reservoir is checked every time immediately before leaving. Always use only one brand of brake fluid; do not allow different modifications to be mixed, as this will lead to a loss of basic qualities. As a rule, DOT-3 or DOT-4 fluid is widely used today. Topping up […]

During operation of the Lada Priora car, it is necessary to check and, if necessary, top up the coolant in the system. It is not allowed to operate the vehicle with the fluid level below the mark by at least expansion tank, as this can lead to overheating and engine failure. Always use only one brand of coolant, do not mix coolants of different colors, [...]

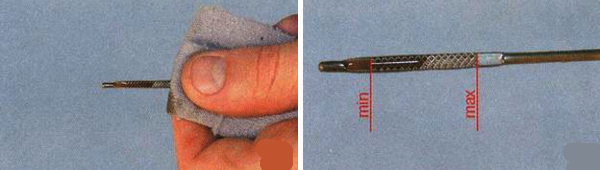

Checking the oil level in the engine crankcase on a Lada Priora car must be done according to the technical inspection card or several times a season, provided that your oil consumption is normal. If the consumption is increased, it is recommended to check it as often as possible or before each trip, especially over long distances, so as not to exceed the critical level. To perform […]

The main purpose of lubrication of body fittings on a Lada Priora car is to increase the service life of all rubbing elements, namely door and hood hinges, locks and latches, as well as the windshield wiper mechanism, fuel tank hatch and front seat slides. To carry out repair work, prepare a standard set of tools, grease and lubricant in an aerosol can. […]

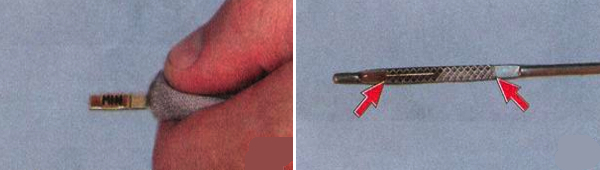

Periodically during operation of the Lada Priora car, it is necessary to check the oil level in the gearbox and, if necessary, top up. These works are carried out according to the technical inspection card or twice a year - in winter and summer. If there is a suspicion of increased consumption, then the check is carried out as often as possible, ideally before each departure, so that […]