The most reliable automatic transmissions. Secondary market: which “machines” should you be wary of?

Although both of these types of transmissions date back to the dawn of the automotive industry, the question in the title is still relevant. In fact, it is impossible to give a clear answer to this - it is enough to know the features of each design in order to compare the pros and cons for yourself. Naturally, we are not talking about extreme applications of cars: say, it’s unlikely to see a Top Fuel class dragster without a two-speed automatic or a Jeeper cutlet without a manual, but here the entire car is built for a specific purpose.

Historically, this is the oldest type of transmission in general; multi-stage gearboxes were invented even before the advent of cars as such. Having gone through a certain evolution and weeded out all unviable ideas, the classic layout of a manual transmission has remained unchanged for several decades.

The basis of a manual transmission is two shafts with gears on them: a primary one, connected to the engine through a clutch or, as an exotic option, through a torque converter (more about them below), and a secondary one, connected to a differential or driveshaft, depending on the selected drive. The fundamental difference between the shafts is that on the primary shaft all the gears are rigidly fixed, but on the secondary they rotate freely. When selecting a specific gear, one of the gears is connected to a clutch, which is rigidly connected to the secondary shaft, while the rest continue to rotate freely.

From the obvious simplicity of this solution comes main drawback such a transmission: at the moment of gear shifting, the clutch, rotating at the same speed as the output shaft, must engage with the gear, the speed of which may be completely different. Therefore, switching rigidity can be overcome either by precise equalization of gear speeds, that is, by shifting gears at strictly defined speeds, or by introducing an additional unit - a synchronizer, which helps to equalize gear speeds until the gear is engaged.

Because of convenience, at least all front speeds on passenger cars must have synchronizers, but they are one of the most weak points Manual transmission. It is not for nothing that on heavy American trucks, where the transmission service life alone is a million miles, there are no synchronizers in manual gearboxes: they inevitably wear out, making gear shifting more and more difficult.

Video: 5 things you should NEVER do with a manual transmission!

But the advantages of manual transmission are obvious:

- Firstly, a minimum of transmission links between the engine and wheels provides manual cars with high efficiency.

- Secondly, even in the event of a breakdown, the manual transmission can be easily rebuilt: it is not difficult to understand its structure.

- Let's add to this the ease of changing gear ratios (it's enough to change just a couple of gears), the ability to work on low-quality oil and tolerance to rough treatment: It is very difficult to “kill” a well-designed manual transmission. And at the same time, manual transmissions are the cheapest, which makes the choice of transmission in the budget segment completely uncontested.

Automatic transmissions

Hydromechanics

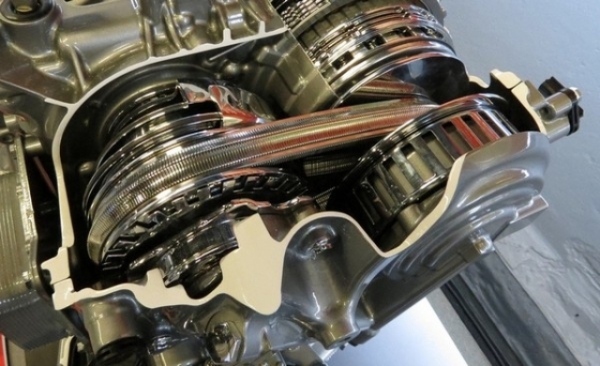

When we say “automatic transmission,” we usually mean a hydromechanical planetary transmission - the oldest type of automobile “automatic”, dating back to the 30s. Such transmissions are based on the property of a planetary gearbox to change its gear ratio when one of its elements (sun gear, satellite block or driven gear) is braked. Since all the gears remain in constant mesh, the gear ratio changes smoothly and without shock - that’s why automatic boxes began to actively develop in those days when “mechanics” did not have synchronizers and required considerable skill in handling the gear shift “poker” and clutch.

From the principle of operation of a planetary gearbox it is clear that it can only have three gear ratios - it’s not for nothing that all “automatic machines” have been three-stage for a very long time. In reality, the gear ratio at each speed of the cars changed more. How so? The fact is that to connect the gearbox with an engine without a clutch, a torque converter was used - a device of two wheels (charger and turbine), closed in an oil volume. This mechanism allows the turbine wheel to rotate at a speed lower than the speed of the blower, that is, in fact, the speed varied even before the three-stage gearbox.

Video: Automatic or manual. Which is better, pros and cons. Just something complicated

Selective braking and connection to the gearbox output shaft of one or another planetary gear unit is performed by a set of friction clutches and brake bands - in old automatic transmissions they were controlled purely mechanically, now the oil pressure in the drives is distributed by valves controlled by their own controller. But the essence of the hydromechanical transmission, although it now has up to 8 steps, remains the same: alas, high losses in the torque converter cannot be avoided, and fuel consumption with such a box will be higher than with mechanics.

The mechanism itself is very demanding on the quality and quantity of oil - even a deviation in viscosity can disrupt the operation of the control mechanisms, causing the “shocks” and “thoughtfulness” familiar to many. This does not mean that automatic transmissions are unreliable: with proper care, they can demonstrate a huge resource. But the convenience of such a box is obvious, especially in city traffic jams, and the introduction of additional stages and forced locking of the torque converter makes it possible to bring their efficiency closer to “mechanics”. An obvious contraindication for hydromechanical automatic transmissions is harsh operation (aggressive driving, off-road) - if overheating or constant rocking driving (back and forth without a pause between starts) are not terrible for a manual transmission, then the automatic transmission in such conditions will have to prepare for an accelerated replacement friction clutches and brake bands.

Robotic boxes

Attempts to automate gear shifting on manual transmissions have been made for a long time, but they all ran into one pitfall: if low-power and slow hydraulic drives could control the clutches and belts of automatic transmissions, then manual transmissions needed high-speed drives. Therefore, actually workable designs appeared on the market only in the 90s, and in essence they were ordinary “mechanics”, where the gear shift clutches and clutch drive were controlled by powerful electromagnets.

Alas, it was these “robots” that ruined the reputation of the idea: their “brooding” and shocks when changing gears only progressed over time, since the clutch release mechanism could not adequately adapt to the wear of its discs. Added to this were regular problems with the solenoids themselves.

Only preselective DSG boxes were able to somehow correct the situation - in them, the next gear was selected before the current one was turned off, and two clutches were activated simultaneously: the first broke the torque of the current gear, the second connected the next one. In terms of comfort and speed, such gearboxes have already been able to compare with “mechanics”, but in terms of complexity they have already caught up with hydromechanical automatic transmissions. Reliability problems remain the scourge of “robots” to this day.

When choosing a new car, the type of gearbox installed on it plays an important role. Today, all used transmissions can be divided into automatic and manual transmissions. What is each type of gearbox, what are the positive and negative characteristics have? Which of these transmissions will ultimately be better? We will examine these questions in the article.

A manual transmission is one of the oldest types of transmissions. Here the driver is directly involved in selecting a gear. Gear shifting is carried out by the driver using a gear selection mechanism and synchronizers, which is why the transmission is called a manual gearbox.

Scheme of a mechanical three-shaft gearbox

Driving usually starts in first gear, and subsequent gears are selected based on the current speed, engine speed and traffic situation. Gear shifting occurs when the engine and gearbox are disconnected using the clutch.

The torque in a manual transmission changes in steps, and accordingly the gearbox itself is considered “stepped”. Depending on the number of gears, gearboxes are 4-speed, 5-speed, 6-speed and higher. The most popular is the 5-speed manual transmission.

Depending on the number of shafts, two-shaft and three-shaft manual transmissions are distinguished. The former are installed on front-wheel drive and rear-engine passenger cars with a transverse engine, the latter on rear-wheel drive and trucks with a longitudinal engine.

Automatic: comfort and convenience

Automatic transmission diagram

Automatic transmission diagram In an automatic transmission, the clutch function is assigned to the torque converter, and the electronic control unit and actuators are responsible for shifting gears: friction clutches, band brakes, etc.

The driver selects the operating mode of the automatic transmission and the direction of movement using the gear selector installed in the vehicle interior. When installing an automatic transmission on front-wheel drive passenger cars The gearbox design is complemented final drive and differential.

Modern automatic transmissions are adaptive, that is, they electronic system equipped with a “memory” of the driver’s driving style. In less than an hour's drive, the automatic transmission will adapt to your driving style.

There are the following types of automatic transmissions: hydro manual transmission gears (classic automatic), manual transmission with two clutches, robotic gearbox and continuously variable variator. But still, an automatic transmission always means a classic hydromechanical planetary gearbox.

Automatic or manual transmission

Let's carry out comparative characteristics two types of transmissions in terms of their advantages and disadvantages. We will take the following criteria as a basis: price, maintenance and repair, efficiency and acceleration, reliability, service life, winter driving conditions, comfort, engine and clutch life, and vehicle behavior on the road.

Price issue

In terms of price, an automatic transmission is more expensive than a manual one. And fuel consumption with an automatic transmission will be 10-15% higher than with a manual transmission. This mainly applies to city driving; outside the city, the difference in fuel consumption will be slightly less.

Maintenance and repair

Maintenance and repair of a car with an automatic transmission will be more expensive. An automatic requires more oil than a manual, and it costs more. Needs replacement and oil filter. Compared to an automatic transmission, a manual transmission is easy to maintain and does not require expensive consumables and spare parts.

Efficiency and acceleration

The acceleration dynamics of a manual transmission are better than those of an automatic transmission, and the efficiency of a manual transmission is higher. A manual transmission makes it possible to realize all the engine power and torque. The exception is robotic transmissions with two clutches.

Reliability

The simplicity of the device compared to an automatic transmission allows manual transmission to claim the title of a more reliable gearbox. Towing over long distances with a flexible or rigid hitch is only possible for vehicles with a manual transmission. It is recommended to transport a car with an automatic transmission only on a tow truck. The operation of a car equipped with a manual when driving in icy conditions, through mud and off-road will be better compared to an automatic.

Service life

And this criterion speaks in favor of mechanics, whose service life is longer. Some mechanical gearboxes can function even after the original car engine fails. The same cannot be said about the automatic transmission, which will only last until overhaul.

Winter driving

It is easier to drive a manual car on slippery surfaces and skid in the snow. For an automatic machine, these actions are not advisable - the transmission oil may overheat.

So, in the six positions under consideration (price, maintenance and repair, efficiency and acceleration, reliability, service life, winter driving conditions), a manual gearbox wins. Let's see how the machine responds.

Comfort

Automatic transmission operating modes

Automatic transmission operating modes An automatic transmission has a higher level of driver comfort than a manual transmission. Even an inexperienced driver will be able to move off calmly and without jerking, without creating an emergency situation. Mechanics require increased concentration and attention from the driver. Constant gear changes and the need to constantly depress the clutch pedal, especially in city traffic jams, tire the driver.

Engine and clutch life

In this regard, the automatic also benefits: it controls the speed and prevents the engine from overheating. On a manual transmission, incorrect gear shifting may result in engine overload. Beginners may forget and fail to change gears from low to high in time, causing the engine to operate at higher speeds.

The same applies to the clutch. In a car equipped with an automatic transmission, there is no need to constantly disengage the clutch.

Car behavior on the road

A car with an automatic transmission moves smoothly, without jerking, and does not roll away on a hill. The automatic transmission has a “parking” mode, in which the engine is disconnected from the transmission and the output shaft of the box is mechanically locked. This mode allows the machine to be held securely in place.

Well, three against six! Is a manual better than an automatic? May be. But developers do not stand still and come up with new and increasingly improved varieties of automatic transmissions. If we take, for example, the acceleration of a car as a criterion, then a manual transmission accelerates faster than a classic automatic transmission, and a CVT transmission is definitely not inferior in efficiency to a manual transmission, and sometimes even surpasses it.

Conclusion

Which gearbox should you choose? There is no consensus on this question. It all depends on what is the driver’s priority, as well as in what conditions he intends to operate the car. If you mainly plan to drive around the city with numerous traffic jams, then an automatic would be the best solution. When driving outside the city, both checkpoints are acceptable. And operating a car in difficult road conditions clearly dictates the choice in favor of mechanics.

Today, the most practical is a manual transmission. But the automatic machine does not lag behind, becoming more perfect and more reliable year after year. If comfort and quick learning driving comes first for you - choose an automatic. If you want to feel the speed and rev the engine to the limit, buy a car with a manual transmission.

Or you can pay attention to the hybrid of automatic and manual transmission – a dual-clutch transmission, which combines the main advantages of both transmissions. The new generation gearbox does not have a clutch pedal, gears change automatically, but the operating principle is similar to a manual gearbox.

When buying a car, it is important to evaluate which automatic transmission is the most reliable and durable. According to statistics, this question is included in the TOP 5 that potential buyers ask themselves when choosing a car. No matter what arguments the supporters bring “ old school» manual transmission, but the fact remains that “mechanics” are gradually being replaced by less problematic “automatics”. It is much easier to learn, very flexible and reliable. After all, if you are buying a car from scratch, you want to get a vehicle that is as responsive and comfortable in every sense as possible.

Which automatic transmission is the most reliable if you have driven a manual transmission all your life and don’t understand all these “new things” at all? This article will evaluate the reliability and performance of each type of “automation”. By the way, there are three of them.

Automatic transmission with torque converter

Perhaps the most common classic version, which is used in most cars. It consists of the gearbox itself and a torque converter that replaces the clutch. Effective interaction of nodes is achieved due to the uninterrupted operation of electronics that monitor the operation of multiple sensors.

Some automatic transmissions have the option to switch to manual control mode. At first, this option was proposed by Porsche, later it was supported by Chrysler, BMW, and some other companies. Let’s make a reservation right away: you won’t get 100% freedom, as in the case of a manual transmission – the electronics won’t allow it. On the other hand, if a consumer consciously took the car with an automatic transmission, he is unlikely to want to “pull the handle” to suit his mood.

The advantages of a torque converter are that it wonderfully dampens shocks and is simply ideal as a damper. However, there are also quite obvious disadvantages: low efficiency and great gluttony in relation to fuel. However, engineers do not stand still - the latest car models consume significantly less gasoline than their predecessors.

Considering the fact that classic automatic transmission has long been chosen as a standard by such companies as Audi, Land Rover, Bentley (GT V8 model), Maserati (Quattroporte model), the box can be considered quite reliable.

Imagine a conventional “mechanics” in which gear selection and closing/unlocking are performed by special servos. Installation robotic boxes transmission in modern cars allows you to avoid failures. This is the main advantage of the DSG “robot” - almost instantaneous response, fairly comfortable use, high efficiency. Fuel costs are also okay. But there was still a fly in the ointment.

If you live in a metropolis, you can enjoy this “spoon” to the fullest. When you need to take off from a standstill or move in ragged traffic jams, the robotic box begins to dull and thinks about commands for too long. In a word, the “robot” lives its own life, and when the driver still tries to move in time, the car twitches noticeably. Such jerks are often accompanied by a strange grinding noise inside the box. This explains why automatic transmission robots, when driving in big city they fail so often.

CVT

It is sometimes also called a “continuously variable” transmission. If you have ridden a modern moped or snowmobile, you will immediately understand what it is. Today there are several types of automatic transmission variators: toroidal, chain and V-belt. The V-belt option has proven itself best. The principle of operation couldn’t be simpler.

Imagine two pulleys with a belt stretched between them. The pulleys consist of two cones. When their location changes, the path of the belt also changes. The design features do not allow the variator to provide reverse gear, but other mechanisms such as a planetary gearbox are used for this.

It would not be superfluous to list the advantages of the variator. This is a smooth ride and very low fuel consumption, as well as a cost comparable to “mechanics”. However, all of them are covered by obvious disadvantages: astronomical prices for repairs and maintenance, the need to use only special oil. By the way, this same oil will have to be changed every 50,000 km, and belts - every 100,000 km.

Another drawback of the “variator” is purely psychological. The motor constantly produces the same sound, that is, the consumer does not hear any twitching or such a pleasant roar. In this regard, the latest models of “continuously variable” transmissions are produced with an imitation of the operation of a conventional transmission.

If you study the range provided by automobile companies and estimate which automatic transmission is the most reliable, only one conclusion suggests itself. Most buyers still choose the classics - and they do exactly the right thing! After all, taking into account the advantages and disadvantages of each type of automatic transmission, it is the classic “automatic” that looks the most stable and responsive, regardless of its operating conditions.

It just so happens that most drivers still prefer a manual transmission, believing that an automatic transmission is still far from ideal, has a number of shortcomings, and simply does not correspond to the image of a man. It is extremely difficult to convince those who want to do everything with their own hands, but for those who are inclined towards choosing a car with an automatic transmission, we will make a short review existing species automatic transmissions, their differences from each other, advantages and disadvantages.

A little history

Engineers began puzzling over how to make the driver’s job of shifting gears easier at the dawn of the 20th century. The first development known to us appeared on the legendary Ford T. Gear shifting of the Ford T two-stage planetary transmission was carried out using two foot pedals: one switched low and high gears; the second included reverse gear. Then, already in the mid-1930s, other American companies, Reo and General Motors, introduced their versions of semi-automatic transmissions. GM's development was a planetary mechanism whose operation was controlled by hydraulics. At about the same time, Chrysler also took up the creation of an automatic transmission, but its developments found more or less real application only on the eve of the Second World War, and even to call them an automatic transmission in modern understanding It was impossible, although a fluid coupling was already used in it.

Have you noticed that the pioneers in the creation of automatic transmissions were the Americans and only them? It is not entirely clear why, but it was the Yankees who were and continue to be the most fanatical about “machine guns.” You still have to try hard to find a car with a manual transmission in the USA. Therefore, it is not surprising that the first truly automatic transmission was developed and put into mass production by General Motors engineers. Already in 1940, it was available as an option on Oldsmobile cars and was called Hydra-Matic. Structurally, it was a combination of a fluid coupling and a 4-speed planetary gearbox with automatic hydraulic control. To understand how significant the emergence of the Hydra-Matic was for the global automotive industry, it is enough to say that not only American but also European manufacturers, including Bentley and Rolls-Royce, soon began installing this transmission on their cars. Moreover, even Mercedes-Benz developed its first automatic transmission based on the Hydra-Matic!

Naturally, the path of the automatic transmission was thorny and was accompanied by a constant struggle with “childhood diseases”, frequent breakdowns and a relatively short service life. But engineers would not be engineers if they could not overcome most ailments. Modern automatic transmissions still require special treatment, but have become much more reliable and durable, have almost equaled the fuel consumption of manual transmissions and have proliferated like mushrooms after rain. Moreover, not only have there been more manufacturers of “automatic machines,” but there are no longer just one, or even two, varieties of the boxes themselves.

"Automatic" with torque converter

This type of automatic transmission is called classic because it appeared earlier than others and before today is the most common. The principle of its operation is both simple and complex at the same time. It consists of two independent units - a gearbox and a torque converter, that is, the latter is not part of the gearbox, but essentially plays the role of a clutch.

The torque converter consists of two vane machines - a centrifugal pump and a centripetal turbine. Between them there is a guide vane—the reactor. The pump wheel is rigidly connected to the engine crankshaft, and the turbine wheel is rigidly connected to the gearbox shaft. The reactor, depending on the operating mode, can rotate freely, or can be blocked using an overrunning clutch.

![]()

The gearbox itself is very similar to a conventional “mechanics”, with the exception of some fundamental important details, providing gear changes with virtually no interruption in the power flow and without driver intervention. A very important point is that there is no rigid connection between the engine and the gearbox. Torque is transmitted to the gearbox using transmission oil, circulating under pressure in a closed circle.

The entire operation algorithm of the automatic transmission with torque converter is monitored by electronics that read and process information from many sensors. She decides when and how to change gears. If the driver pedals softly, gear changes will occur quickly enough so as not to rev the engine too quickly. high speed and thereby save energy (fuel). However, as soon as the electronics receive a signal about a sharp and intense press on the accelerator pedal, it will immediately switch to a mode that allows you to unleash the full potential of the engine. However, in order not to mislead the electronics and provide the driver with the most optimal performance characteristics of the gearbox in specific conditions, many manufacturers provide the ability to switch between pre-programmed modes, such as economical, sport or winter.

Often, automatic transmissions allow you to switch to manual mode gear shifting, either by selector or steering wheel paddles. For the first time, such a “trick” appeared on Porsche cars and was called Tiptronic. Moreover, Tiptronic is not a type of automatic transmission at all, but only trademark. Each manufacturer has its own (Steptronic for BMW, Autostick for Chrysler, etc.), but it was Tiptronic that became a household name, similar to Xerox for copiers. And yet, manual gear shifting in an automatic transmission is nothing more than additional functionality that does not carry too much meaning for the vast majority of drivers. In the end, you don’t buy an automatic transmission to change gears manually, and electronics, in any case, will not give the driver complete freedom of action.

The undoubted advantages of an automatic transmission with a torque converter, like any other non-manual gearbox, include comfort. In addition, the torque converter is an ideal torsional vibration damper and is capable of dampening strong shocks that are transmitted from the engine to the transmission and vice versa, which has a beneficial effect on the life of the power unit, transmission, and chassis. On the other hand, such a box also has a lot of disadvantages. The main ones are a relatively small resource and low efficiency. The latter is due to the fact that useful energy is spent on shoveling and heating the oil by the torque converter. The pump that creates pressure in the control lines also takes a lot of energy. All this leads to increased fuel consumption, although over the past few years engineers have managed to make some progress and curb the appetites of the classic “automatic”.

Among other disadvantages of an automatic transmission with a torque converter, it is worth noting the inability to start the car “from a pusher” and the need to carefully monitor the condition of the transmission oil and change it in a timely manner (and it is more expensive than oil for “mechanics”). Moreover, this even applies to the so-called maintenance-free boxes, which are serviceable, sooner or later, but still awaits.

Many drivers complain that torque converter automatic transmissions are too lazy, especially 4-speed ones, and this is partly true. But here it is important to understand that manufacturers sometimes deliberately make the boxes not too fast in order to meet the car owner’s expectations in terms of fuel consumption. This is confirmed by the fact that in cars where dynamics are very important, modern 6-, 7- and even 8-speed automatic transmissions with a torque converter demonstrate excellent operating speed. Just look at the ZF 8HP, which is installed on many models of Audi, BMW, Land Rover, and even extraordinary cars like the Bentley Continental GT V8, Maserati Quattroporte, ...

Robotic gearbox

To understand how a robotic gearbox works, you need to imagine a regular “mechanics”. The only difference between them is that servos—actuators—are responsible for closing/opening the clutch and selecting gears in the “robot.” Most often this is a stepper electric motor with a gearbox and an actuator, but there are also hydraulic actuators. They are controlled by an electronic unit. At the electronics command to switch, the first servo drive depresses the clutch, the second moves the synchronizers, including the desired gear. Then the first one smoothly releases the clutch. That's all, actually.

The seemingly ideal scheme is simple, with high efficiency and lower fuel consumption compared to a torque converter. But there is one catch: in order to avoid jerking and not mock the clutch, when shifting gears, the “robot” permanently breaks the connection between the engine and the wheels, which is why unpleasant dips occur during acceleration, the only way to get rid of them is to reduce the time switching But how to achieve this? It turns out that the solution was found even before the outbreak of World War II, when the Frenchman Adolphe Quegress invented a dual-clutch gearbox for Citroen. True, the matter did not reach production then, but already in the early 1980s the Frenchman’s idea was picked up by the Americans and Germans. Well, “robots” with two clutches have gone to the masses at the behest of the Volkswagen concern and its DSG (Direct Shift Gearbox). Using its example, we will consider the principle of operation of such a box. Porsche, by the way, calls it PDK, Ford and Volvo call it Powershift, Audi calls it S-Tronic, Mercedes-Benz calls it Speedshift DCT.

In theory, everything is very simple: the DSG has two secondary shafts, with driven gears and synchronizers located on them, and two primary shafts inserted into each other like a nesting doll. Each shaft is connected to the engine through a separate multi-plate clutch. The gears of the second, fourth and sixth gears are fixed on the external input shaft, and the first, third, fifth and reverse gears are fixed on the internal shaft. When first gear is engaged, the first clutch closes, transmitting torque through the input shaft to the wheels. At the same time, the secondary gear of the second gear is blocked, that is, the second clutch is half ready to engage and is only waiting for the electronics to give the appropriate signal. And so on with the next transmissions. For this principle of operation, such boxes are called preselective.

The main advantage of preselective “robots” is the speed of gear shifting. For the standard 6-speed DSG it is eight milliseconds (0.008 sec). Fantastic result! And if you consider that dual-clutch transmissions are more comfortable than a classic automatic transmission and more economical than a manual transmission (the electronics selects the optimal gears and, unlike the driver, is not lazy about switching them), it is easy to conclude that long-term success is guaranteed. Moreover, engineers were able to solve most of the reliability problems that plagued the first samples of preselective robotic gearboxes.

If we talk specifically about the DSG, then it is probably worth mentioning some of the features of its operation, noticed during the actual operation of a car with such a gearbox. For example, at moments when there is a need to sharply accelerate and the artificial intelligence of the “robot,” in theory, should quickly respond to intense pressure on the accelerator by downshifting, the DSG “freezes” for a while, thinks and only then does what it should. But the DSG leaves an even less pleasant impression in the taffy mode, when the car moves at low speed and the rhythm of this movement is jagged. At such moments, the “robot” is clearly subjected to violence against itself, as evidenced by the grinding noise from the box and the nervous twitching of the car. Naturally, the DSG is most susceptible to breakdowns at such moments.

At one time, it was believed that “robots” with two clutches were not capable of transmitting high torque, and therefore their scope of application was limited only to civilian passenger cars. However, the Ricardo company proved the opposite by developing an analogue of the DSG for the 1000-horsepower Bugatti Veyron coupe and thereby eliminating all questions.

CVT

Believe it or not, a CVT is the oldest invention used in a car after the wheel. They say that Leonardo da Vinci drew a variator back in 1490, but the continuously variable transmission turned into a real mechanism, which received the corresponding patent. late XIX century.

Finding itself unclaimed, the idea lay idle until 1958, when one of the founders of DAF, Hub Van Doorn, presented the small car DAF 600 or A-Type, as it is also called, at the auto show in Amsterdam (don’t be surprised, in those days DAF produced not only trucks, but also cars). It was an unremarkable baby, with the exception of one thing - the revolutionary CVT (Continuously Variable Transmission) transmission at that time. Frankly speaking, few people believed in the variator back then, but Van Dorn did not plan to give up. The Dutchman thought that the best way The participation of CVT cars in competitions will demonstrate to the skeptics that they are wrong. At first, the DAF 600 was raced on rally tracks, then, by chance, the CVT was tested on a Brabham Formula 3 chassis... Alas, it soon became clear that the CVT was incompatible with powerful engines, and therefore the path to big-time motorsport was barred. In 1975, however, Enzo Ferrari himself became interested in a continuously variable transmission, but later decided to close the project and transfer his energy to developing a turbocharged engine. And the swan song of the CVT in motorsport came in 1993: after the Williams Formula 1 team tested a car with a CVT and achieved very good results, the International Automobile Federation strictly banned the use of continuously variable transmissions in big-time sports.

Coincidentally or not, it was in the 1990s that the CVT began its entry into the mass auto industry and continues this path to this day. Moreover, engineers have already partially solved the problem of compatibility with powerful engines. In any case, now CVT successfully works with engines whose output significantly exceeds the 200 hp mark. With. Maybe there will be more!

There are CVTs different types- V-belt, chain and even toroidal. The V-belt is the most widespread, so we will consider the principle of operation of a continuously variable transmission using its example. And this principle is extremely simple. A V-belt variator consists of two pulleys, between which a belt is tensioned. Each of the pulleys, in turn, consists of two cones with their sharp ends facing each other. The cones can move and move apart, changing the working diameter along which the belt moves. When the cones come closer, the belt is pushed out, that is, it moves along a larger diameter, and when moving away, it moves along a smaller one. As a result, the main task is accomplished - a smooth change in the gear ratio without the need for any physical switching.

Due to the peculiarities of its design, the variator cannot provide reverse movement, so additional mechanisms are used to move the car in reverse in the CVT. For example, a planetary gearbox.

The ubiquitous electronics are responsible for how the variator works. Her department also includes transmission management. Yes, yes, there are such variators, but, as we understand, these transmissions are exclusively virtual, programmed by engineers to solve specific problems directly related to the characteristics of the engine and the general purpose of the car.

Ideal smoothness, moderate appetite and a price comparable to a classic “automatic” - these are the main advantages of the variator. However, all of them are seriously threatened by the shortcomings of the CVT, which still prevent the continuously variable transmission from claiming leadership among automatic transmissions. First of all, this is expensive maintenance and repair. The variator requires changing special (and therefore expensive) transmission oil every 40-50 thousand kilometers, and every 100-150 thousand kilometers the belt may need to be replaced. In addition, you need to know that a car with a CVT can only be towed with the engine running (only in this case the necessary pressure is created to ensure lubrication and reliable engagement of the belt with the pulleys), or by partial or full loading.

However, difficulties with towing also arise for cars with classic automatic transmission. If for some reason the tow truck does not arrive, but the car needs to be towed, just follow a few simple rules:

- tow the car with the engine running;

- keep the speed no higher than 40 km/h;

- try not to travel more than 40-50 km at a time;

- make stops for 15-20 minutes after every 40 km.

Afterword

Each automatic transmission has its own characteristic advantages and disadvantages. However, with the passage of time and the development of technology, problems with “automatic machines” are becoming less and less obvious. No mechanism can be ideal, but engineers have always strived to get closer to their cherished goal and will continue to strive. Who knows, perhaps in the future alternative automatic transmission designs will appear - reliable, economical and inexpensive - and they will be destined to supplant the boxes that we discussed in this article.

Which of the existing automatic transmissions is still better? Unfortunately, it is impossible to answer this question unequivocally, but if you follow trends in the auto industry, it is easy to notice that manufacturers consider robotic gearboxes with two clutches to be the most promising. CVTs occupy second position, and classic automatic transmissions, apparently, are becoming obsolete, and therefore are not being developed very actively.

But, we believe that you should also choose a transmission based on the class of the car and who will drive it and for how long. If you prefer a calm driving style, then a classic automatic transmission will satisfy you, and if you like fast and aggressive driving, we advise you to pay attention to preselective gearboxes. In sports mode, their “rate of fire” can compete with the speed of a real racing driver. And for a small car, a regular “robot” or a CVT will be just right.

Hi all! Today's article is devoted to the types of gearboxes, their differences, advantages and disadvantages. If you don't know which gearbox is better - automatic, manual or CVT, you will find the answer below.

To understand the advantages and disadvantages of each of the boxes, you need to understand their structure.

Mechanics.

The oldest type of automobile transmission. Torque is transmitted through gears, which are engaged and disengaged by the gearshift lever. The mechanism itself is designed in such a way that only one pair of gears can be turned on at one time.

The clutch serves to separate the engine and transmission. When the clutch is disengaged, the engine torque is not transmitted to the gearbox and a shift is made at this time. When driving a manual car, the driver fully feels the car and controls it.

In order to understand how a manual transmission works, I advise you to watch this video:

Machine.

The mechanical part of the automatic transmission is based on planetary gearboxes. The gearboxes are engaged through the so-called. clutches, which in turn are engaged by hydraulic pistons.

The operation of the machine is controlled using electric or hydraulic “brains”. A torque converter is used as a clutch - in a simplified form, these are two propellers, one of which spins the other with a flow of oil. Due to this, there is no constant rigid connection between the shafts and the torque is transmitted nonlinearly, with increasing speed, it is possible to transmit more torque (modern automatic transmissions can block the torque converter and due to this they save great fuel).

To understand how the automatic transmission works, I suggest you watch this video:

CVT.

The only continuously variable transmission type! The design with pulleys of variable radius was invented by Leonardo Da Vinci.

The principle of operation of the variator is that the gear ratio is changed steplessly by changing the diameters of the pulleys between which the belt is tensioned.

The main drawback lies in this belt and pulleys - these are highly processed parts made of expensive high-strength materials.

Marketers present this type of box as modern solution allowing you to use all the engine power for acceleration! Yes, in fact, only a variator can smoothly change the gear ratio, keeping the engine at maximum power speed! But the problem is that the variator transmits power very poorly, and in itself is very capricious.

All other types of gearboxes are able to rigidly (through gears) connect the primary and secondary shafts (modern automatic transmissions provide locking of the torque converter), thereby eliminating slipping). In the case of a variator, a rigid connection is impossible; when the belt slips, the oil boils and sharply increases the friction force, thereby eliminating slipping; each such slip wears out the belt and pulleys. As a result, after a mileage of 80-150 thousand km, the gearbox completely fails and needs to be replaced. Contract and refurbished boxes are a lottery, their resource is unknown, and a new box costs 300-500 rubles.

This is how the variator works:

Robot.

A robot is nothing more than an electronically controlled mechanical box. On robotic transmissions, the clutch is controlled electronically and the gears are engaged electronically.

In general, the solution is not bad, but on small budget gearboxes there are roars when turning on gears and a delay when switching; on sports gearboxes with two clutches this problem is solved, but such boxes are much more expensive!

This is the most efficient type of automatic transmission today! The only disadvantages include the inability to randomly (selectively) shift gears and the increased complexity and cost of gearboxes with two clutches.

Here's a short video about how a robotic gearbox works:

So which gearbox is better?

It is impossible to give an unambiguous answer to this question because... tastes differ!

If you like to “drive” a car or live in the “backwoods” and traffic jams for you only come in bottles, you don’t have the problem of choosing – mechanics. The reason is simple - the most reliable type of gearbox that does not require expensive maintenance and expensive spare parts.

If you live in a big city, then after the first month of manual operation of the car you will see this picture:

The cost of servicing a car manually will be the lowest, and fuel consumption will be minimal, but this car will not be the most convenient to drive.

If most of the time you crawl through city traffic jams with their start-stop mode, you should definitely choose an automatic or CVT. Yes, the automatic transmission will show higher fuel consumption, and the CVT will be annoying due to the uniform howling of the engine during acceleration, but in the urban cycle the difference is not critical, and the clutch on a manual transmission does not last more than 50-60 thousand km in traffic jams.

If you choose between a CVT and an automatic, I recommend choosing an automatic, since its service life is 5-6 times higher than that of a CVT, it does not require replacing belts (which is not cheap) and, in extreme cases, the car will retain the ability to move.

A CVT after running 100,000 km on any car is a lottery! And if you lose, in the worst case scenario, you end up with half the cost of the car.

The robotic transmission is seen as some kind of compromise between automatic and manual, but in city driving the car will be annoying with frequent shifts and, most importantly, the robot does not know how to jump through gears. Those. The automatic transmission can drop 2-3 gears down and begin intense acceleration; the robot can only shift 1 gear up or down. There is no difference in fuel consumption between a robot and a mechanic and the coefficient useful action both transmissions are the same! For those who like to drive, sports versions of robotic gearboxes provide the fastest acceleration due to the operation of two clutches.

Conclusion.

Which box to drive is up to you to decide! Personally, I prefer classic automatics or mechanics. The CVT is also good, but the price of repairs... But a two-disk robot is not a thing for mass use, although overclocking with it is amazing!

That's all for me today. I hope that now for you the question “which gearbox is better, automatic, or manual, or CVT?”

If you have anything to add to this article, or have comments on the text, leave comments.